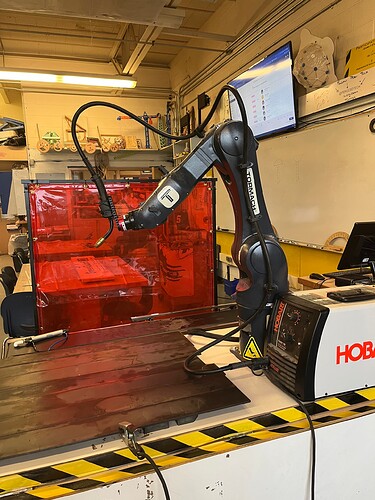

Looking for a better way to hold the welding torch to the ZA6 . Does anyone have a 3D print file? I am using a camera rig adapter plate and hose clamps.

I don’t want to hijack your thread, but was curious how you control the wire feed? Looks like you’ve got the trigger held closed on the torch. Is there a contractor on the main rig so that the robot controls the feed, or some other system?

@sorgule - a ZA6 customer here in Madison used a flat bar mounted to the J6 flange and a pair of hose clamps. Tormach is working on a more elegant solution and should have something for sale in a month or two. I’ll post a link in these forums when it’s ready.

@bigtchopshop - the leads to the torch here at Tormach are disconnected at the welder and routed instead to a contactor controlled by one of the digital outs. The DOs are 24V hi/low but most manual MIG welders need an open/closed connection to control the torch, hence the contactor. There’s a quick tip video here on how to wire up a contactor to a ZA6 and we’re working on a 2 contactor accessory that just works with the M12 output connectors.

@Rogge summed it up nicely- that is exactly how I’m setting it up. The welder will be controlled directly through the robot program with a relay. I’ll make some video clips on how it’s setup.

Here is an example code to incorporate talk to text with a welding program:

https://drive.google.com/file/d/1oUi4gtP0rX02f7zG7jnHMQVnbA9ZtPRs/view?usp=sharing