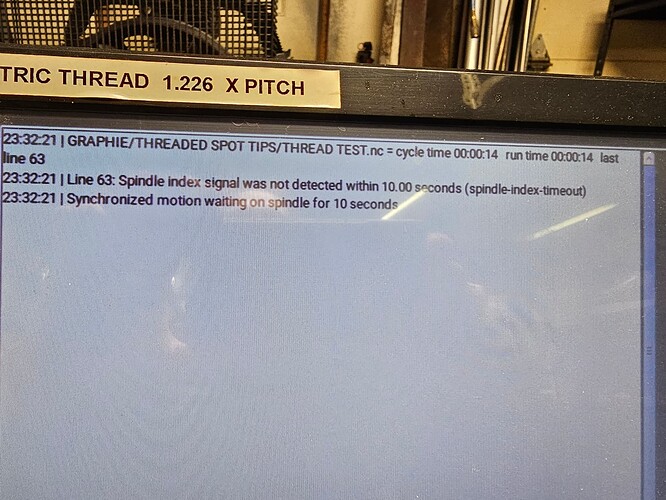

Hi, is there a way to test the spindle encoder, I had thread to do tonight but when the threading tool goes to the start position close to the part, the tool stays at this position and after a couple of second, I get an alarm that it can’t synchronize.

If I rotate the spindle by hand, I can see the A and B led from the encoder in the status page,

with the encoder DRO counting.

Thanks for any help, Jeff

Incorrect value set somewhere “fat finger” I call it.

I had the spindle rotation get set in reverse on a lath drill operation in Sprutcam yesterday!

I Have no clue how it changed in the cam settings. Best I can figure is I bumped the mouse or keyboard when it was highlighted!  Your running code and instantly something is wrong! Broken bit, and tool post out of alignment 5 seconds later.

Your running code and instantly something is wrong! Broken bit, and tool post out of alignment 5 seconds later.

Go to here.

Spindle encoder

Type ADMIN ENCODER TEST

To run encoder test.

1 Like

This admin encoder test command does not work on the lathe

Thanks, I tried with many programs, and it does not work.

ADMIN ENCODER TEST does not work on the lathe

1 Like

Ok, replaced the encoder and threading is working now, got some help from Tormach, Thanks

2 Likes

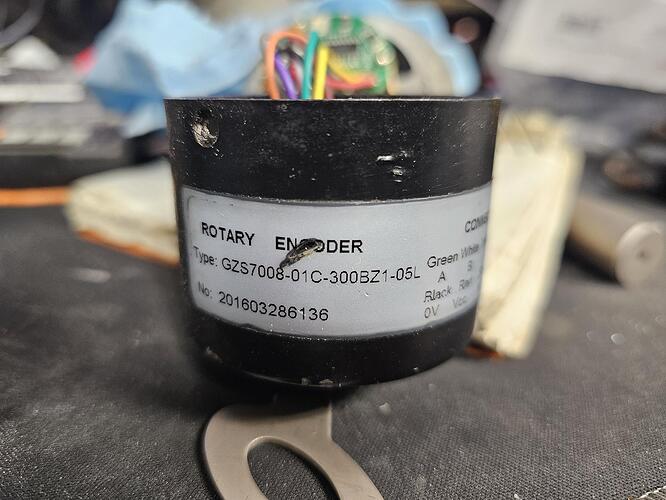

Daniel, would you take a picture of the sticker on the encoder and upload it? It’s all washed off.

Mine is making noises and they are backordered on Tormach.

OK, will do it tonight, still have the old encoder.

Sorry for the late thank you.

Hard down with the flu.

Did you try to rebuild it?

I was thinking of trying. Bearings would be the obvious thing.

No, did not try to fix it, the problem was not the bearing but no signal, I have looked inside and there is not much to fix but, maybe the bearing.

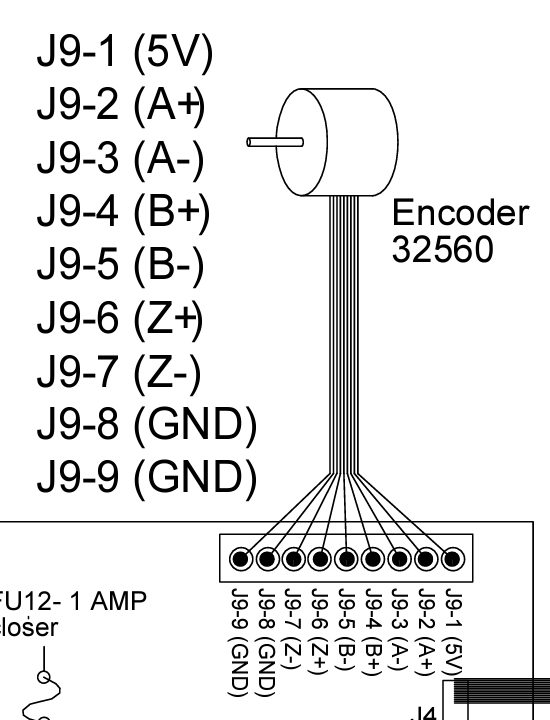

This is the wiring diagram for the encoder

First I would try looking for the magnet, they fall out and they are usually about 1mm diameter. Then find a bigger magnet and wave it around in there it might grab the other magnet or the metal blocking the signal. Then try testing for continuity on the 3 sensors in it with the external magnet. Last I would try to clean it out, blast it with compressed air and alcohol to see. If that does it.

A photo of the inside could help too. I have a feeling it’s going to be impossible to remove the sensors.

It may be easier to think of it like this. Your repairing 3 magneticly actuated switches. If there is no signal on any of them then either the magnet is gone or it’s got enough ferrous metal in it to block the magnetic field from actuating the switches.

Also you might be able to find a stereo repair shop that could look at it for you. There are some old electrical engineers out there repairing high end audio equipment.

Ok thanks for the info.

Supposedly they may be back in stock next month.

We’ll see.