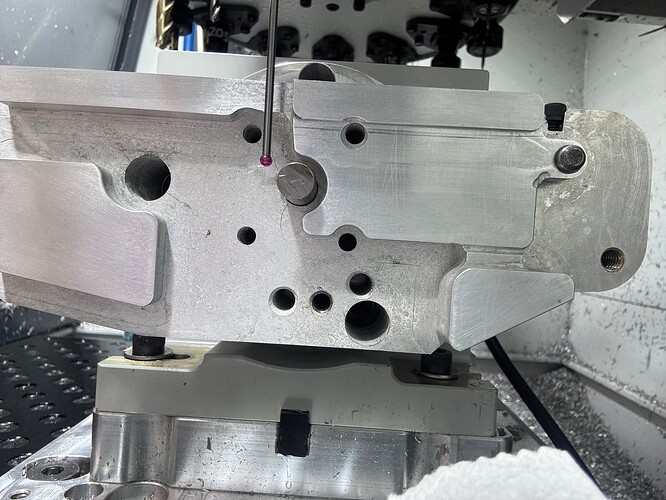

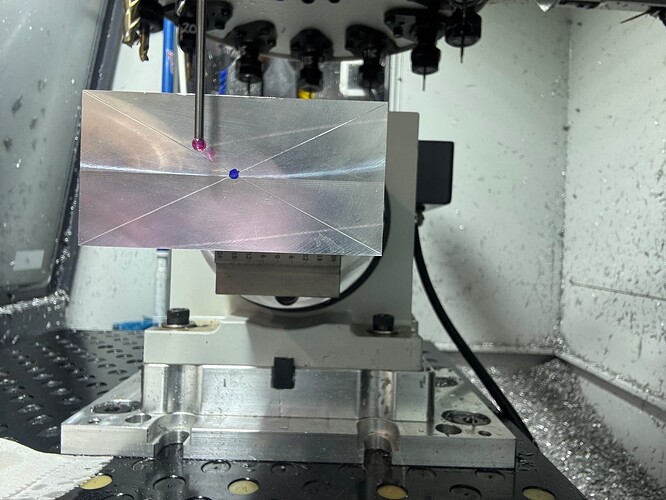

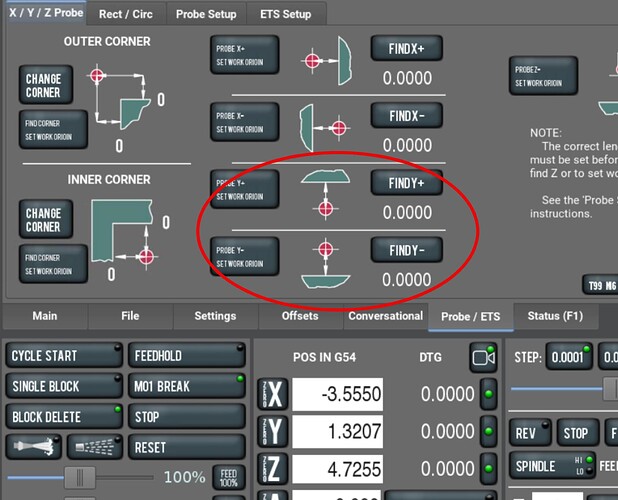

All the probing routines Im using for Ian’s procedure are all basic Path Pilot routines. The positions the probe tip is in, in the pictures, are from me using GOTO Z0 Y0 manually by entering into MDI after I have performed all the steps in Ians procedure.

Sorry to write a book every time and sorry if some of this is redundant but just trying to cover all the info and address your guys input. I do appreciate the input.

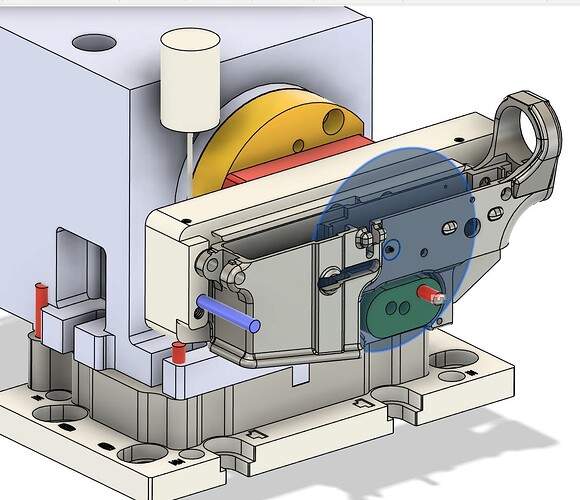

My original plan was to do just that by following the video in the screenshot below and David Loomes scripts. SO, the reason I’m not using the built in find A center is as I understand it that “could” introduce additional variables in accuracy in my final setup. You even suggested this previously in one of your posts to me in the fact that swapping out fixtures in a single set up could introduce positioning issues down to the play in the screws. You did not say exactly that BUT it stopped me in my tracks making me realize that “could” be a bit issue. The reality is swapping out multiple fixtures in a single set up is the issue, RIGHT???.

As described before the G59 setup requires several steps as described here.

1. Perform Path Pilot find A center script by using the Tormach ER-40 faceplate and 1” precision gauge pin to find the center. “ALL GOOD”

2. Store this location in the control as an alternative work offset for the Micro Arc (I used G59) just like in the video. Watch the video if you have time, its 2 parts.

3. But then I need to remove the ER faceplate and replace that with my fixture, SO that is the problem with going that route. IF there are any inaccuracies in my fixture in “relocation onto the micro arc” I’m screwed. RIGHT? For me, absolute position is necessary to be successful in making this part. I’m not only making a few of these and I need a repeatable setup for now and the future.

4. The saved G59 location makes it easy for future recall of the Micro Arcs center, and makes perfect sense for machining on “raw stock” from scratch, BUT could be the kiss of death for a previously machined part going in for Op3, RIGHT???

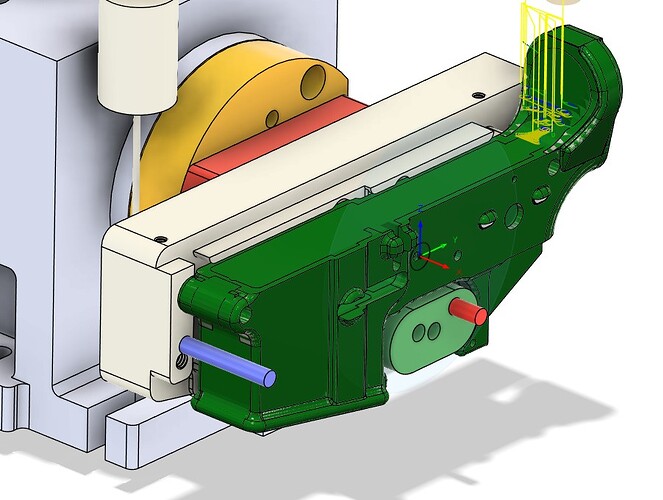

5. SO when Ian suggested this procedure, it made a lot of sense to me for the fact that I could do the set up from beginning to end with “my fixture” already mounted to the Micro Arc.

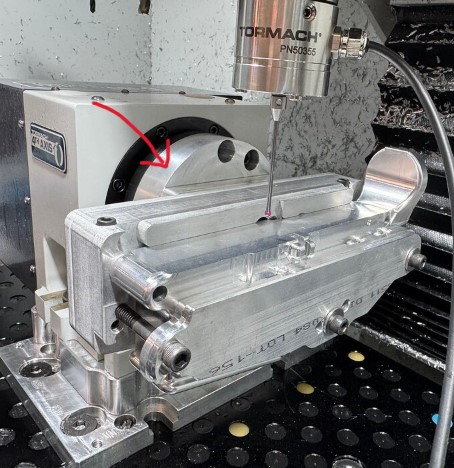

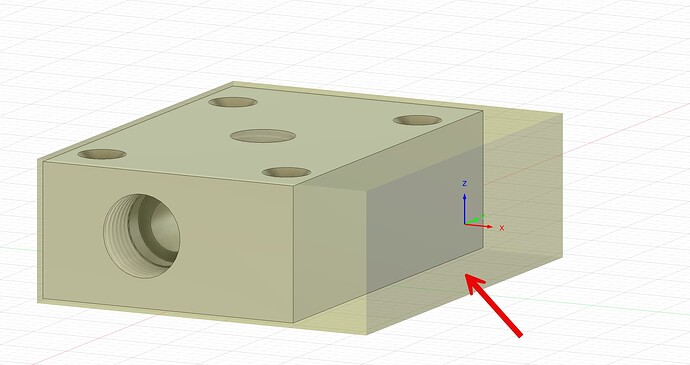

Here’s a thought, Kind of a crazy one, yesterday I started thinking about using the outer diameter of the Micro Arcs mounting ring OR the GTM adapter plate shown here with arrow as my probing surface and running the Path Pilot (probe A find center) I checked the clearance in CAD, and it looks good. Quesion is, if the OD would be mounted absolutely concentric to the Micro Arc’s center. ??? I even reached out to Steve Strange of GTM Manufacturing to get his input on the OD probing, have not got a reply yet. IF there is clearance, I could do this with my fixture mounted and I would be good to go. I have my doubts the OD is a good option to probe. I guess running an indicator on the OD would tell the story right?, I did not think of that last night. WHAT do you guys think of this method? It would be a simple solution for future milling of this part for sure!

![]()