Hey All,

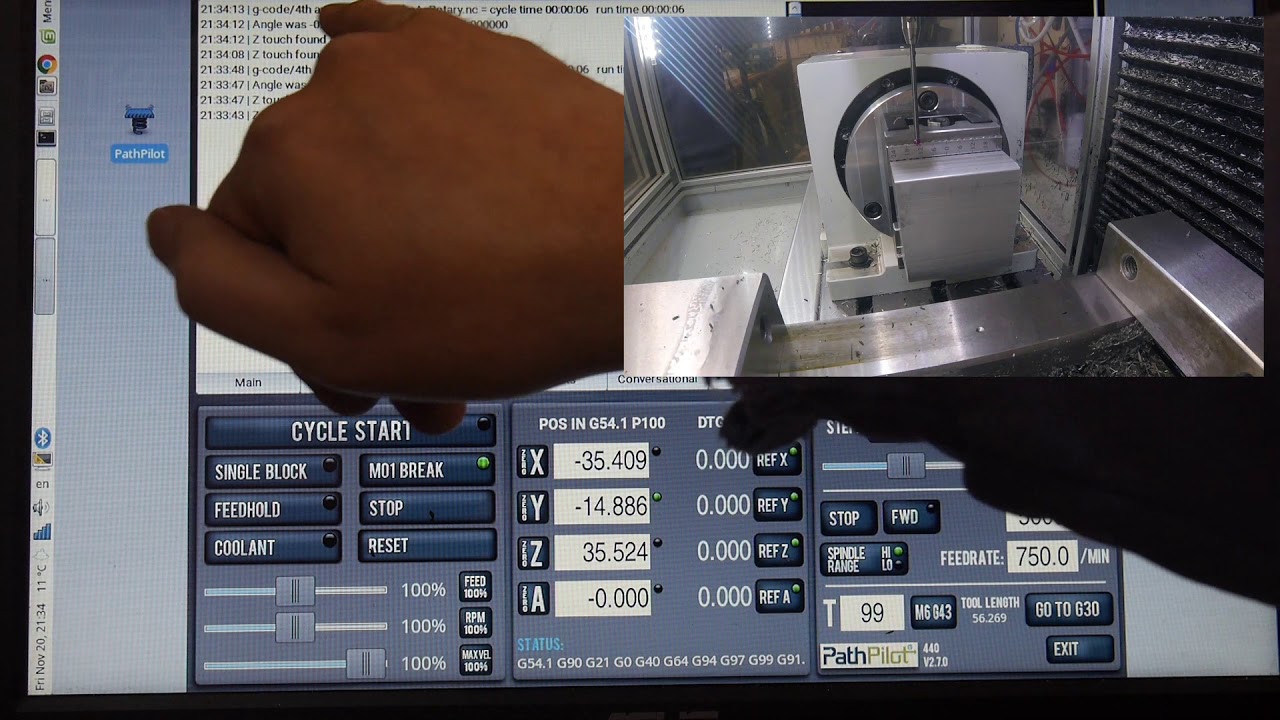

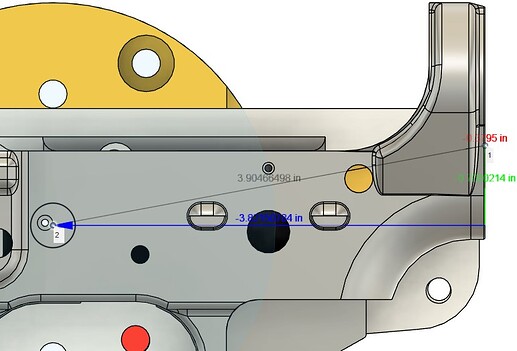

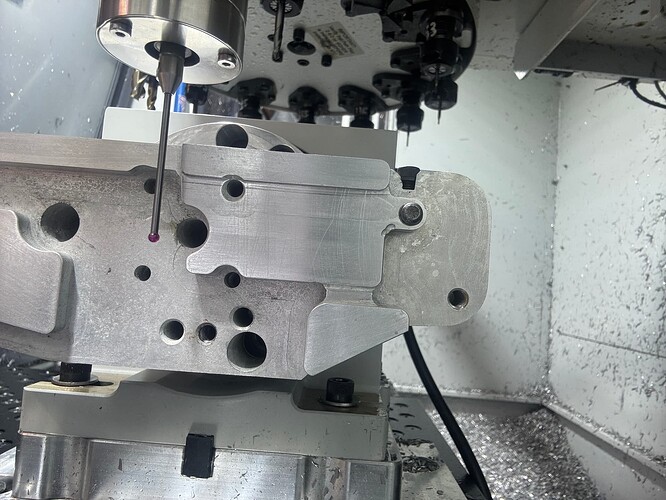

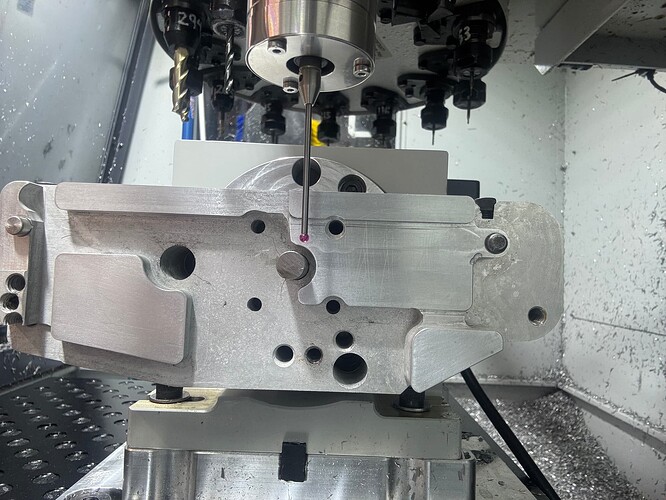

As a continuation of this post Im still working on wrapping my head around indexed 4th axis work and very close to milling my Op 3.

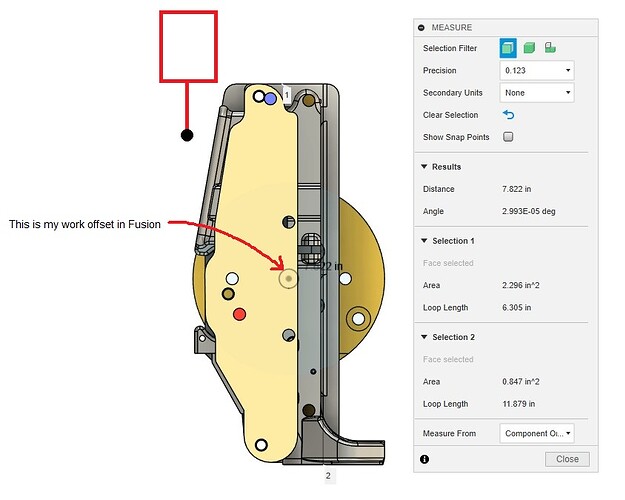

The video Jerry_Chapman posted does a great job of walking you through the process of setting up Micro Arc for indexed 4th-axis work, but does not go though a key detail I need to know about. In the video, he runs the (Find Rotary Axis Center) path pilot probing routine and stores the work offset as an alternative permanent work offset as G59 for use in future Micro Arc setups, which is great!

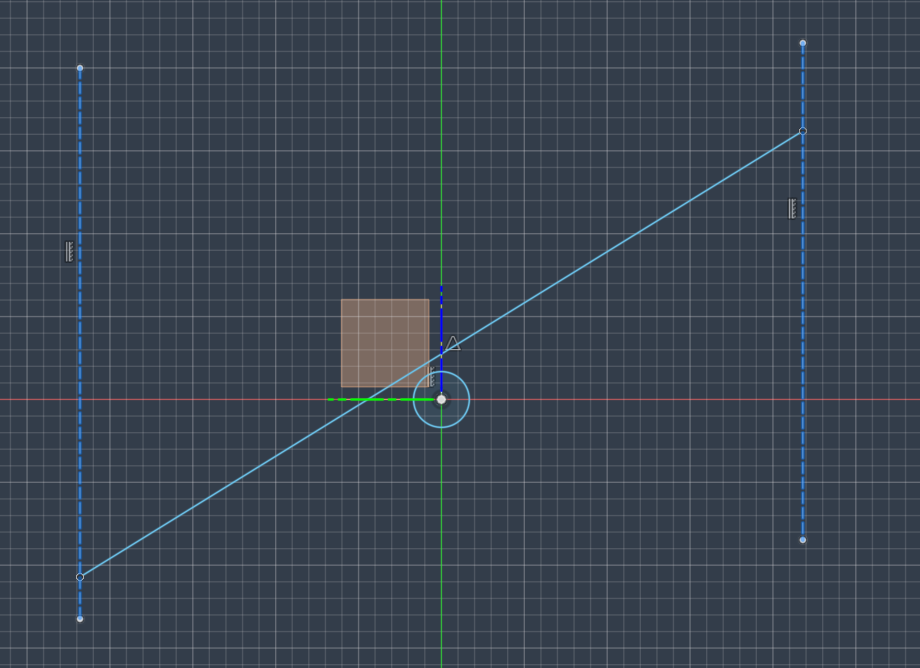

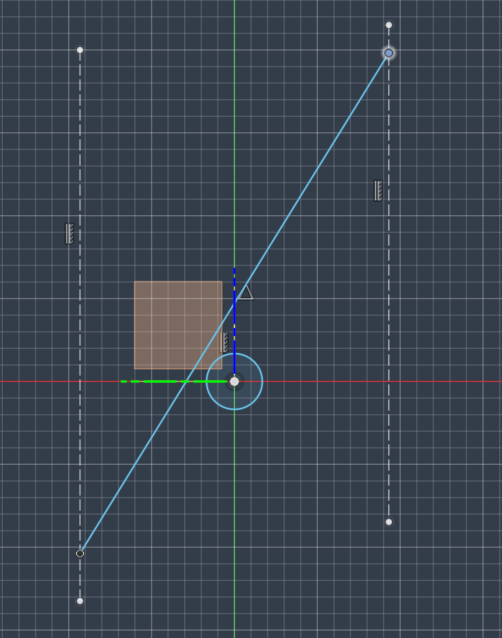

Next step is to use David Loomes probing script to make final micro adjustments to the Z & Y Micro Arcs center of rotation to compensate for our limit switches not being perfect. Also great!

Then we run David’s Probe_A Z&Y script to make the rotational adjustment to get our part and or stock perpendicular to the tool face. PERFECT!

BUT

What I’m unsure about is how do I reset up after I reboot the machine using the stored G59 work offset and be ready to mill?? He does not get into this in the video. I’ve done it, but I want to confirm I’m doing everything correctly.

Here is the procedure as I’m understanding it.

• After I reboot the machine, I home XY&Z as normal.

• DO I NEED TO HOME A? OR I assume it really does not matter per the next steps.

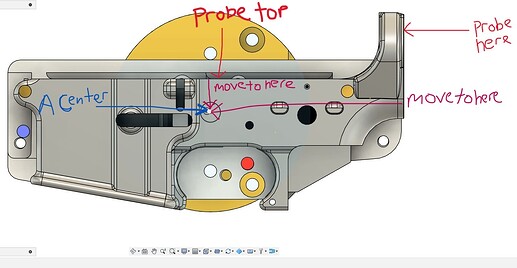

• I now bring the machine into G59 work offset and command the machine to GOTO Z0, Y0.

• I do NOT move the machine axis.

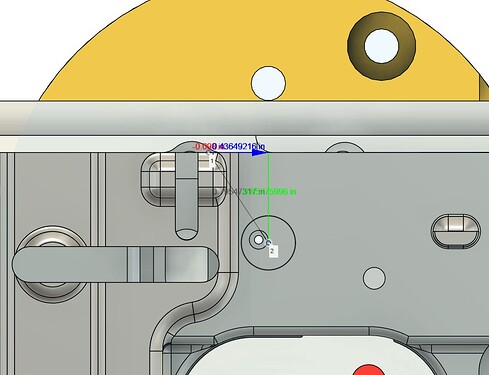

• I now go back to G54 as this is the offset my part is programmed in for milling my Op 3 work and ZERO out my Z & Y position from the last step. This will now put me in G54 center of rotation for my A Axis.

• I now run the ProbeA_Rotary to make the rotational adjustment to get my part & fixture perpendicular to the tool.

• I now probe my part face in X and I’m ready to machine.

• Does this sound right? Am I missing anything?

QUESTIONS

Once I reboot the machine and preform the above steps, do I need to rerun David Loomes Z & Y micro switch adjustment script to adjust for the micro switches? I think I do right? Any time you reboot the machine and home the inconsistencies of the micro switches are in play, right? And WILL require adjustments, Right?? OR would the Saved G59 be perfect???

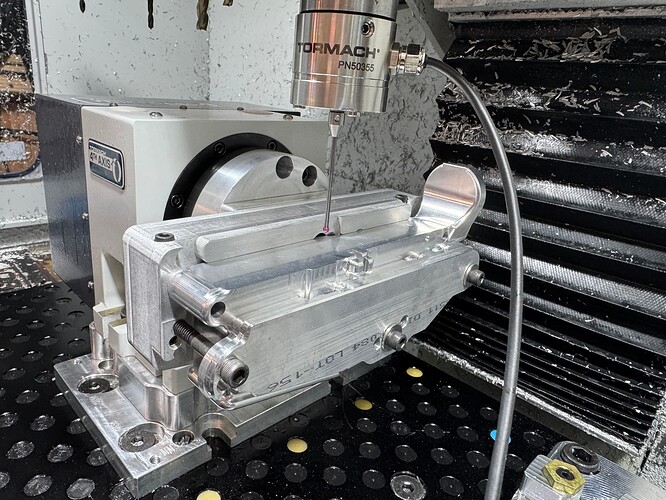

Here is where it gets tricky for my setup, sorry for long explanations here.

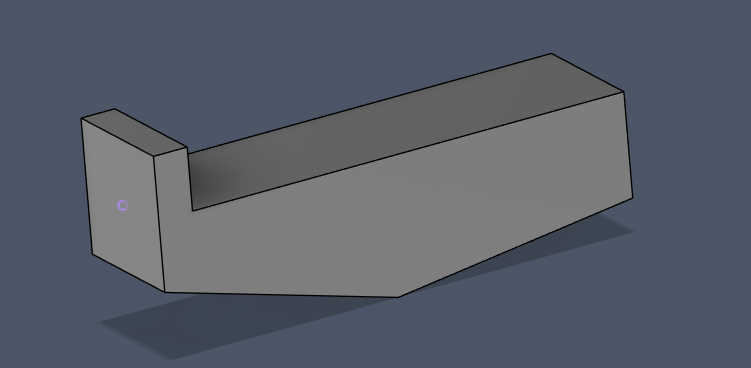

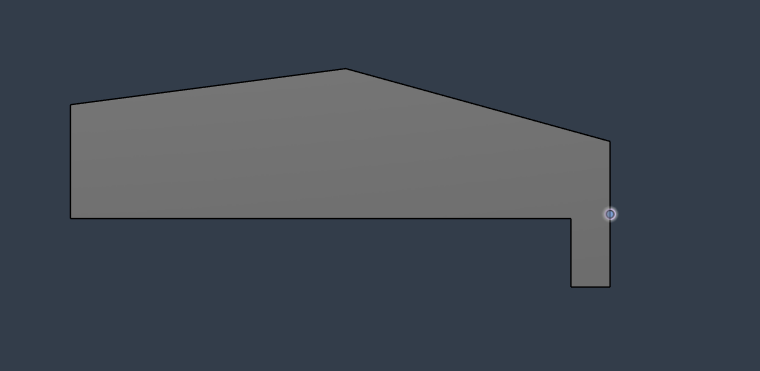

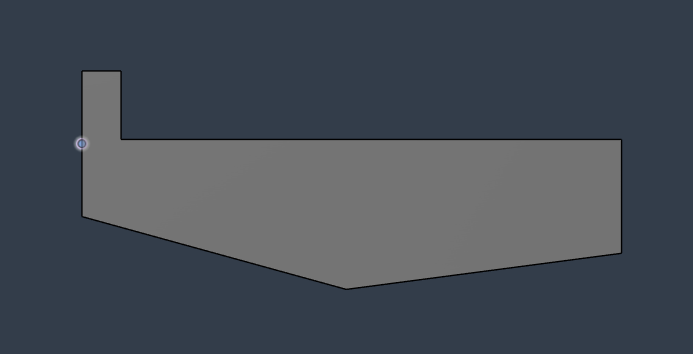

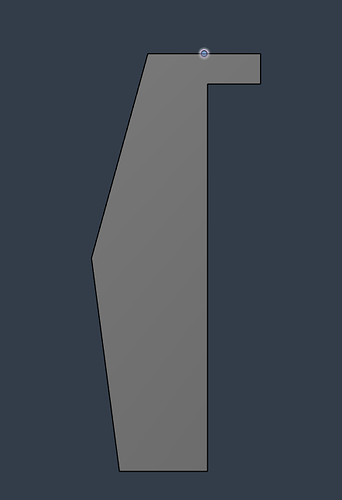

Since my fixture and part is like 81/2-9 inches long I can not run David’s ProbeA Z&Y script with it attached to the Micro Arc.

SO I would need to take my fixture off the Micro Arc, and replace it with my self centering vice and a small enough piece of stock in order to run David’s Probe_A Z&Y script. Im thinking I woudl use a no hole 123 block for this since all side are perfect and In theory would yield better results than a unmachined stock.

For a clearer picture of this watch Davids Video. (7 Min video if you have not watched it yet)

Additional input welcome.