Hey All,

Im working on an AR-15 (airsoft) lower receiver and Im finally getting close to making chips on it.

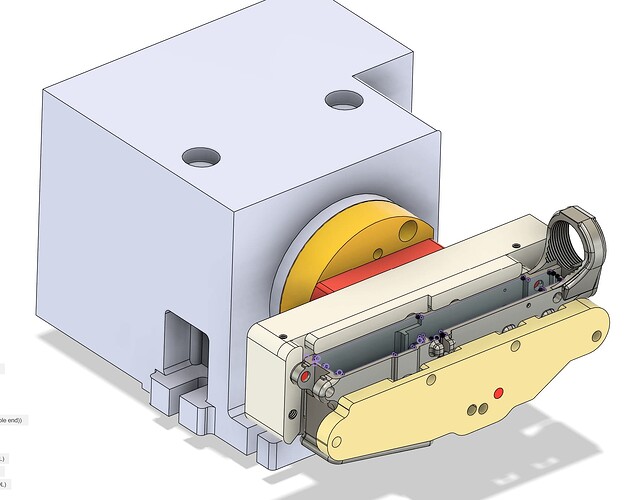

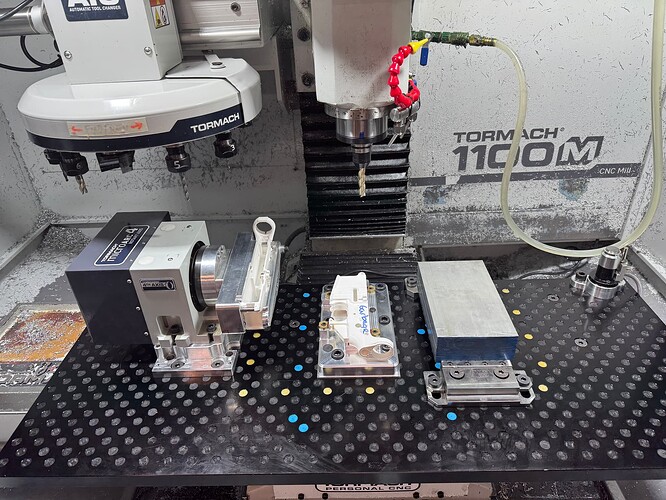

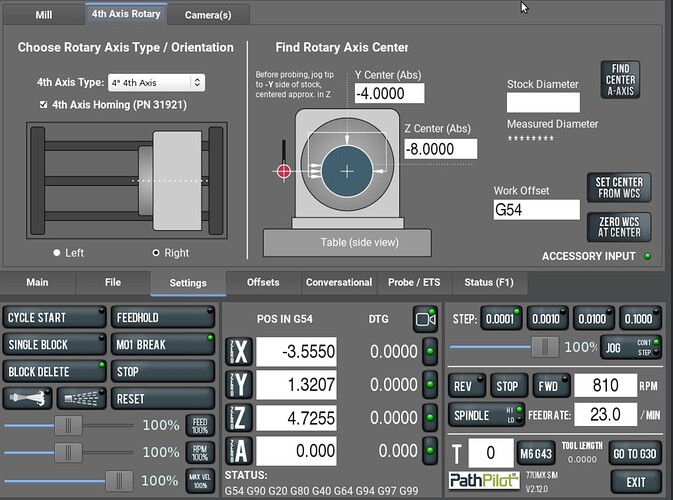

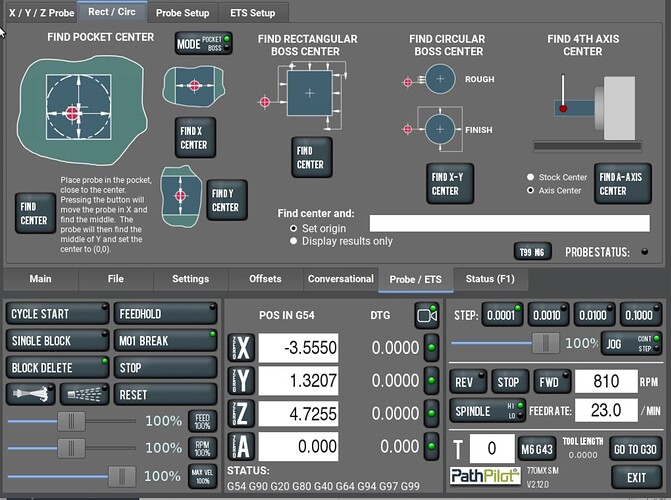

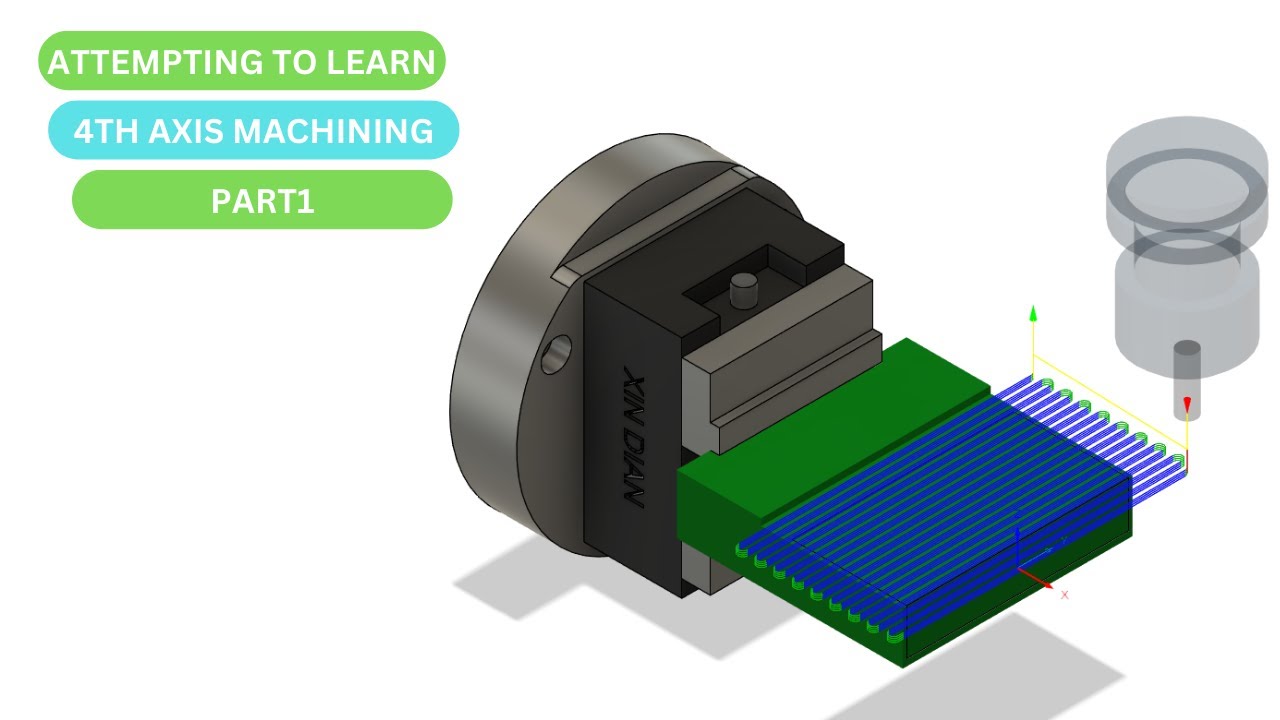

Quick run down Op 1 & 2 are 3 axis, and Op 3 is indexed Micro Arc, Im on an 1100M with a Tormach Passive Probe, doing CAD/CAM in Fusion. I need help with the practical probing setup for my work offsets for the Micro Arc. Ive been thinking about this for weeks, but im not exactly sure how to set up for the 4th axis. And because this is a specialized set up there are no real resources out there I can find as a step-by-step guide. Norm at Tormach has told me just that, and I have not found any videos on indexing. I think its pretty lame there is nothing on this! The part will be indexed on all 4 sides, top, bottom, front, back, plus the angular rotation to drill and tap the hand grip threads. Here’s a picture of everything as well as a screenshot.

Questions.

• How do I establish my starting rotation of the Micro Arc so that my top part face (as seen in my screenshot) is perfectly parallel to the table? HOW do I probe for this?

• Once I get the rotation exactly where I want it do I just hit zero A axis?

• Currently in Fusion, I have my work offset at the center of the Micro Arc in Y&Z with X on the face of the GTM adapter in (part in yellow). I know that when programming for parts that rely on the center of rotation for 4th axis, this would be the typical setup aside from where I have my X. SO, would this be a common OR a standard setup for an indexed part?

• I want to establish my work offsets by probing existing milled faces or features. Im not sure I want to rely on the actual fixture. BUT if you have input on how reliable that would be let me know.

• How would you guys approach setting the work offset for this setup?

Thanks

Bill