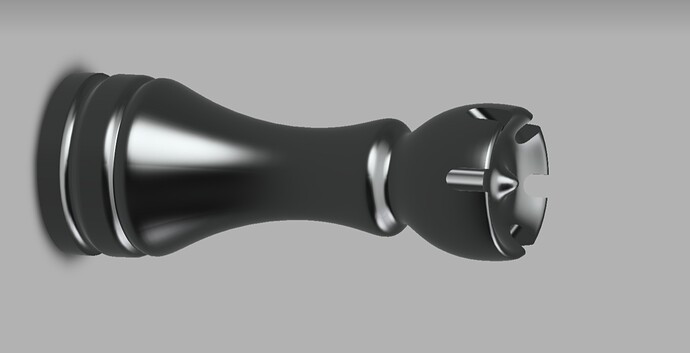

Here is the WHILE loop that I added to the program to make this work in an automated fashion. I added this to the rook since I was already done with the queen but I have used this technique a few times for non-chess parts.

#1 = 10 (Roughing Passes)

#2 = 2 (finishing passes)

#3 = [#1 + #2] (total passes)

#4 = 0.013 (Rough DOC)

#5 = 0.004 (Fine DOC)

#6 = [[#1 * #4]+[#2*#5]] (total material removed)

#7 = 0 (Z holding place value)

(DEBUG, #1 = num rough)

(DEBUG, #2 = num fine)

(DEBUG, #3 = total passes)

(DEBUG, #6 = material to remove)

M1

(----- Start of G-code -----)

()

G7 (Dia. Mode)

G18 (XZ Plane)

G90 (Absolute Distance Mode)

G40 (Turn Cutter Compensation Off)

G91.1 (Arc Incremental IJK)

G20 (units in inches)

G54 (Work Offset)

G30 (Park Tool)

T2828

G96 S 351 D 2000

G95 F 0.0120 (Units per Revolution Mode)

M8 (Flood Coolant ON)

M3 (Spindle ON, Forward)

G0 z0.5 (go to known position)

G10 L20 P1 Z[0.5 -#6] (move enough for total material removal)

o101 while [#3 GT 0]

G0 X1.3000 ( go to safe X, then start Z before issuing G71)

G0 Z0.2600

(G71 P1192 D0.0100 F0.0120 J0.0060 L6 I0.0030 K0.0030 R0.0100 E1)

(Finish Pass)

G96 S 351 D 2000

G95 F 0.0020 (Units per Revolution Mode)

G0 X1.3000 ( go to safe X)

G0 Z0.2600 ( go to start Z)

G42 (Cutter compensation - on)

G0 X0.0000 Z0.2600

G1 X0.0000 Z0.0000

G1 X0.1185 Z-0.1310

G2 X1.0923 Z0.0000 I0.1051 K0.5795

G1 X1.2000 Z0.0000

G40 (cutter compensation - off)

G1 X1.3000 ( go to safe X)

G0 Z0.400 ( go to safe Z)

o103 IF [#1 LT 2] (check to see if that was the last roughing pass or any finish pass)

M1

G10 L20 P1 Z[0.4+ #5]

#2=[#2-1]

(DEBUG, #1 = num rough)

(DEBUG, #2 = num fine)

o103 ENDIF

o102 IF [#1 GT 1] (check to see if still roughing after this)

(DEBUG,#1)

M1

G10 L20 P1 Z[0.4+ #4]

#1=[#1-1]

(DEBUG, #1 = num rough)

(DEBUG, #2 = num fine)

o102 ENDIF

#3 = [#1 + #2] (total passes)

(DEBUG, #3 = total passes)

o101 endwhile

(“o-code subroutine for profile”)

(Note: all profile subroutine code is in parenthesis)

(o1192 SUB)

( G1 X0.0000 Z0.2600)

( G1 X0.0000 Z0.0000)

( G1 X0.1185 Z-0.1310)

( G2 X1.0923 Z0.0000 I0.1051 K0.5795)

( G1 X1.2000 Z0.0000)

(o1192 ENDSUB)

M9 (All Coolant Off)

M5 (Spindle OFF)

G30 (Park Tool)

()

(----- End of Profiling -----)

M30 (end program)