I have a program that I have used on a HAAS and it calls out a G50 (maximum RPM to keep a constant surface footage). What is comparable for a Tormach 8L? Thank you for your help in advance.

Allen,

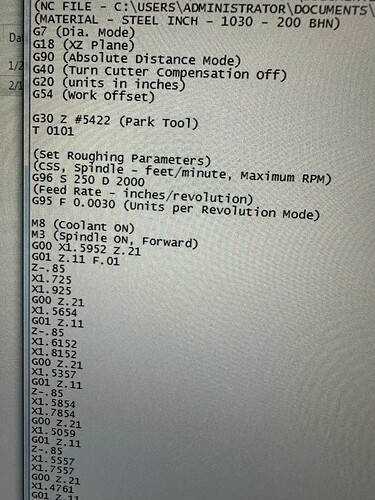

In a G96 command you would include an S value to specify a maximum spindle speed.

Thank you,

Norman

Thank you for your help. I will try that.

Its actually a D. G96 S500 M3 is spindle forward at 500sfm. G96 S550 D2500 is Spindle forward at 550 sfm with a limiter at 2500rpm. G97 S550 is a constant RPM of 550.

Donald,

You are correct, I made a mistake there.

Thank you,

Norman

A side note to consider when setting cam options for lathe operations. I use sprutcam and there is an option for RPM over CSS and it pretty much always needs to be checked! What it does is sets an rpm of spindle to a value while the machine moves tool to and from the surface to begin or finish cutting. If you don’t have this set and you use CSS it will try to turn the spindle in relation to the cutter distance from centerline. This can damage most lathes because the machine is trying to spin up the spindle or down in relation to the rapid movement of the tool moving to or away from the work surface! This problem is also detailed in the lathe section of “CNC Programming handbook” by Peter Smid