I recently ran into an issue that’s occurred a few times where when using the keyboard to move the bed left (-x) the bed over-travels and hits a hard stop… Thunk.

This is after the system was properly referenced. (Hard Stop check box is clicked in settings).

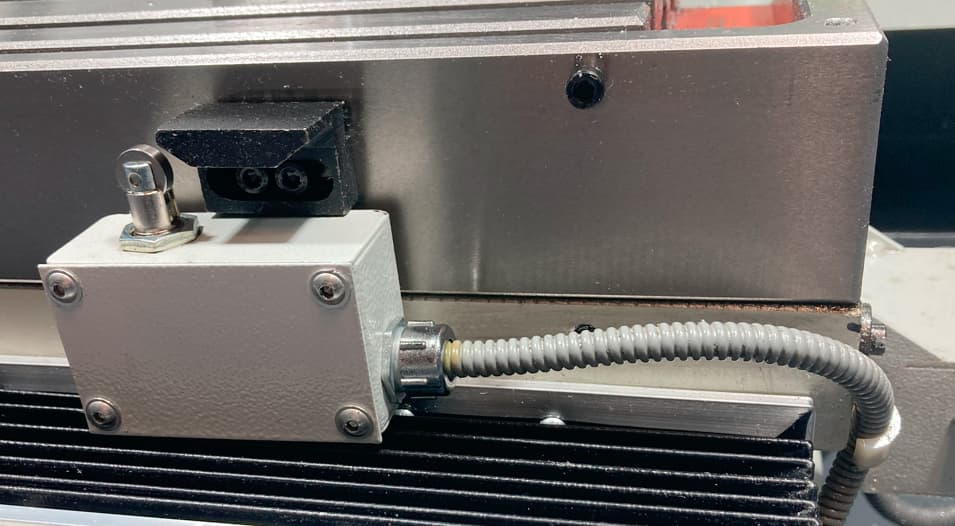

So I initially thought there was an issue with the limit switches until I realized that the Stop on the bed on the right side can never make contact with the switch with the bed all the way left. Why is it there?

Secondly, manually pressing on the limit switch both X and Y does nothing, It doesn’t stop movement when referencing, it doesn’t stop movement when jogging, it doesn’t stop movement when commanding a position.

This 770Mx is new with about 30 hours on it so far and I was going to check on the gibs since I have chatter at 12OClock and 6 O’clock when cutting circular features under load. However this over travel and stop issue seems more pressing at the moment.

Any insight would be appreciated. The image below shows how with the bed all the way left the limit switch is nowhere close to being activated by the block.

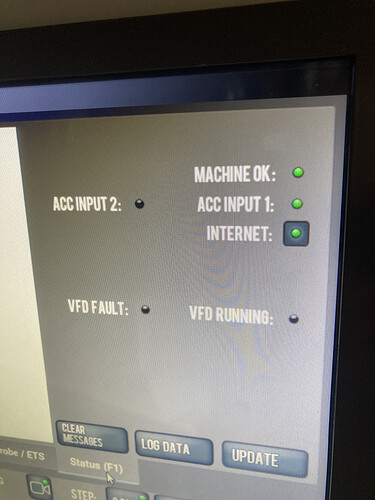

Do we know where to find the status of the limit switches in pathpilot now? Mine are missing from the status page as the troubleshooting and tutorials show it.