I have set up a 1/8 endmill in a tool holder so I can machine chamfers down to, well 1/8 inch holes. Much better than a c-sink.

I have an 8L.

I am setting up the tool in the offsets page and I am struggling with front and back angles as well as the reverse tool path created by the conversational chamfer tool. Not sure why Tormach did it from left to right for any of them. I have 45 years as a general machinist and some experience with CNC, makes no sense to me.

Anyway, conversational is not an option, even with a boring bar.

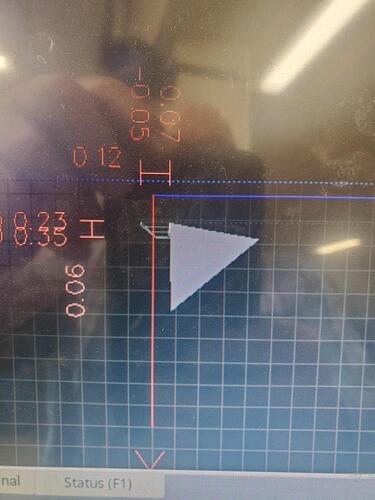

So, I am using the Profile app. Have tried numerous BA: and FA: setting in both the tool list and the geometry tab in the profile page. Setting from -180 to 180 in both, nothing gives me the correct tool which then results in gouging errors.

This should be simple and it likely is.

tool 14, orientation 3, "Carbide boring ba:30 fa:45 w:.125

I have no issue writing the G-Code, but the point is not to and for my students to be able to do it.

any thoughts?