HI,

I’m running a thread mill operation and I need to remove more material. So, bringing the tool in closer. Is that something that needs to be changed in the program or can it be done on the tool offset page? If on the offset page what would need to be changed? Thank you!

I would do it on the program not on the offset. If you change it on the offset your feed will be wrong.

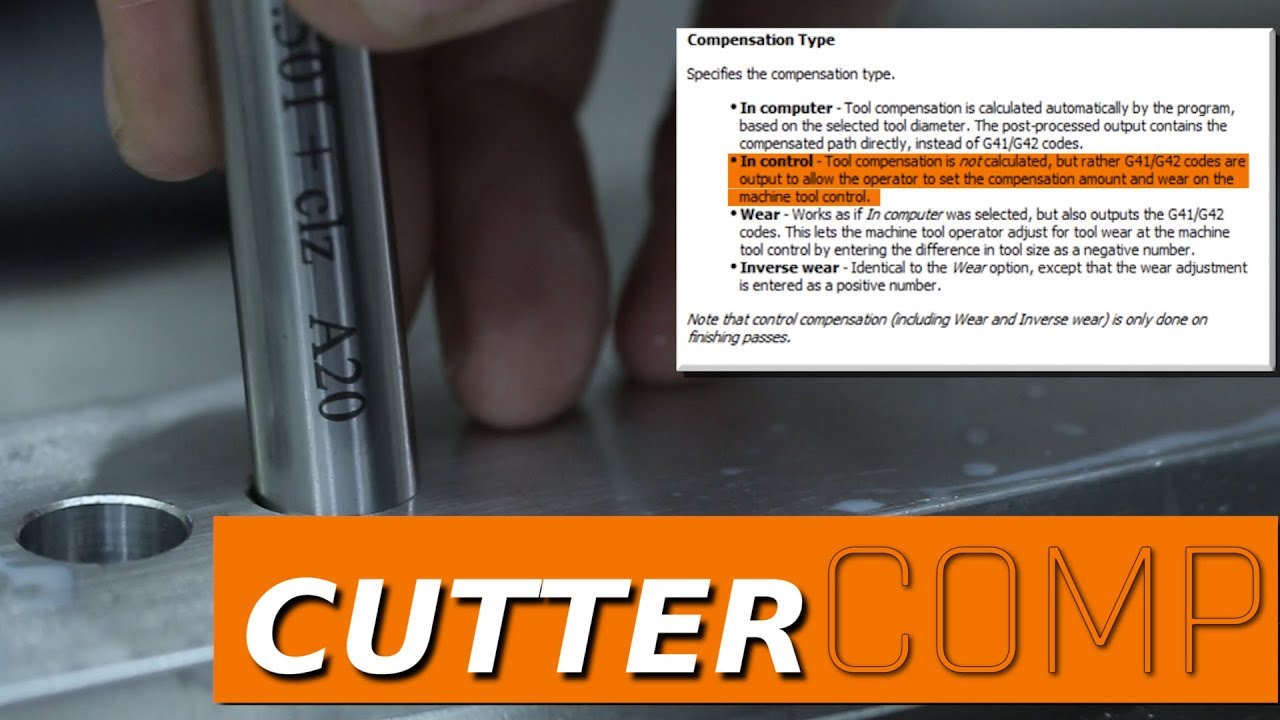

You can absolutely change it on the offset as long as you have instated cutter compensation.

how would you go about doing that?

The video Davie posted explains it well. Enable cutter comp in your CAM system, then adjust the diameter on your offsets tab in PP based on which cutter comp method you have chosen, following the descriptions in the video.

FYI, in control tends to cause a lot of errors and headaches for pretty much everyone, in pretty much every cam system. I only ever use “wear”.

Your cad software should give you the option of left, right computer or wear. Left or right I states compensation using the diameter you place in the tool definition page. The cutter has to move least the radius of the tool and the code matches the geometry on the print. Computer posts the code without cutter compensation and the code is offset half the diameter of the tool you picked in the cam program. Wear is the same as computer except it instated compensation with a diameter of zero allowing you to offset the tool in the diameter wear column. A positive offset tells the control you are using a bigger tool so moves the cutter away to take a smaller cut. A negative offset means a smaller tool so the control moves the tool farther in and fakes a larger cut.