I am a few day off from receiving my 1500MX, so lots of questions come to mind. I primarily mill 6061 with YG1 aluminum specific tooling. I am interested in what techniques others use to establish decent speeds and feeds for their tools. I am not interested in pushing each tool to it’s max capacity, I want to achieve reasonable speeds and feeds. Here are a few approaches I have read about and experimented with:

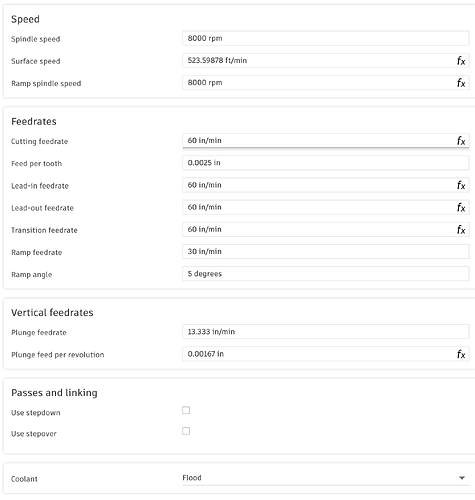

- Look up the manufacturers specified surface feet per minute or whatever variables they provide and calculate the resulting theoretical best or fastest scenarios. Then start a job with the feed rate turned down to about 25% and increase it until everything looks and sounds good. Stop when it no longer looks /sounds right.

- Plug the manufactures tool specifications info into GWizard calculator and experiment with these figures by slowly increasing conservative/aggressive slider

- The Zig Zag method. Start with a conservative speed/feed from the mfg spec sheet, and sequentially increase rpm, increase chip load, increase rpm, increase chip load…. increase rpm (suggeested from Lakeshore Carbide).

Just curious what you guys have found works best for you?

Richard