I bought a never-used microarc 4 that will be delivered on Monday. I need to whip up a sub-plate to allow mounting to a Saunders PCNC 1100 tooling plate. Saunders allow download of their sub-plate CAD file. This supports M/MX mills as well as direct connection to the 1100 table, none of which I need … so I modified the sub-plate to remove these features.

I’m curious about their design though, especially the location of the 5/16"-18 holes for attaching the microarc. Curious if anyone here has a similar setup? If you could change the design of SMM micro-arc sub-plate, what would you do?

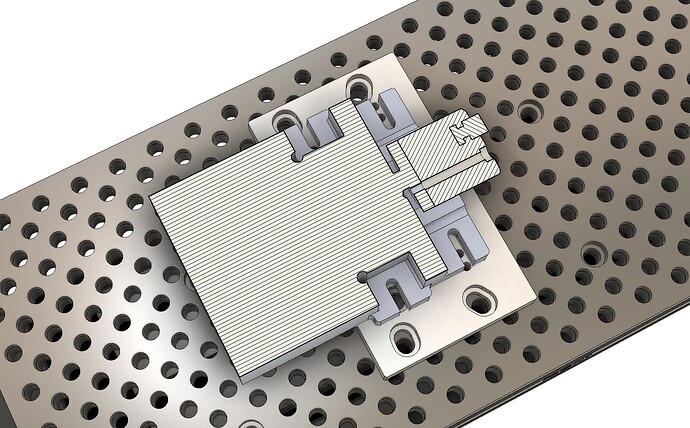

Here is a screenshot of my simplified plate, with the microarc mounted (and partially sectioned away for ease of viewing):