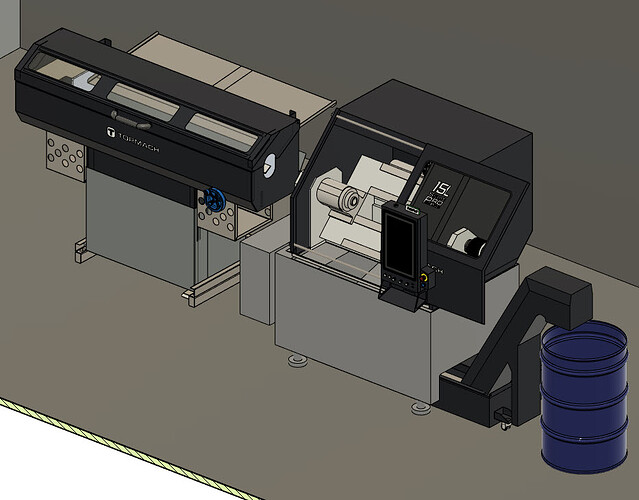

I was just wondering from Tormach when something along these lines is comming.

Also wondering if this would be something the community would be interested in.

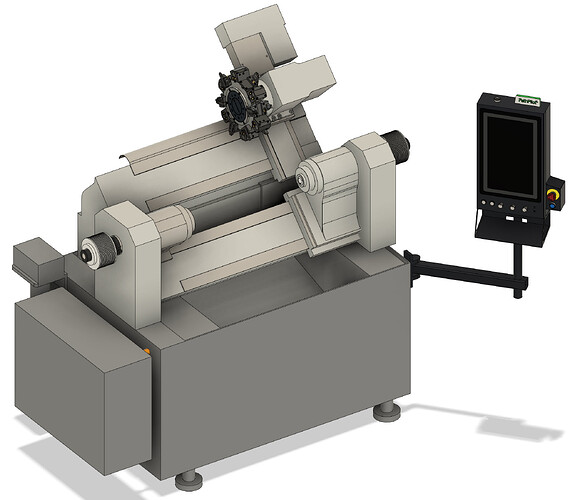

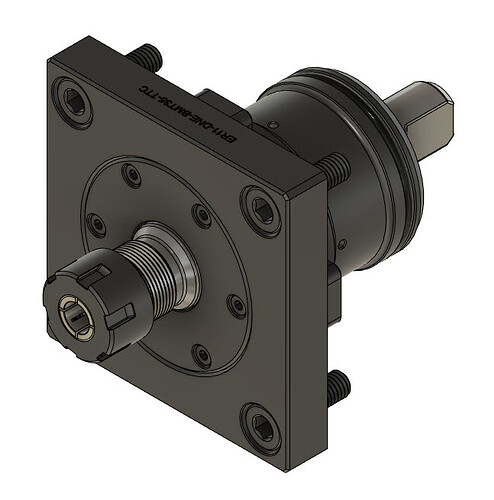

Main Spindle A2-5 with 16C Collet integration.

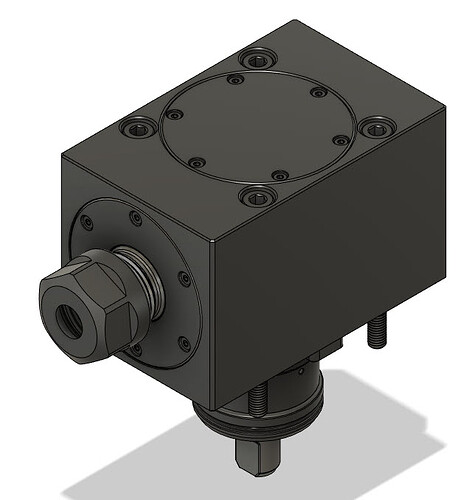

Sub Spindle A2-4 with 5C Collet Integration and Parts Ejector

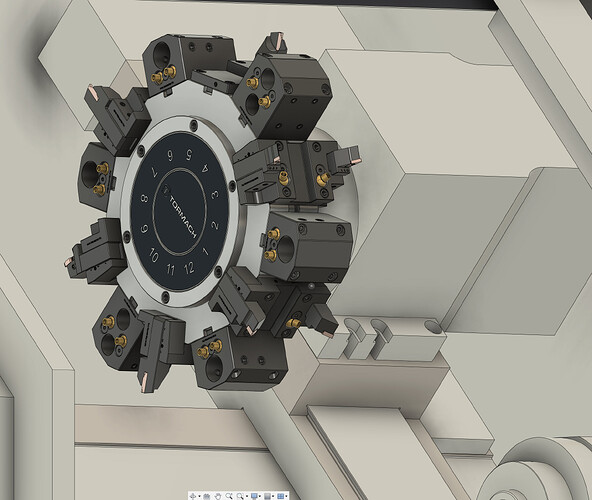

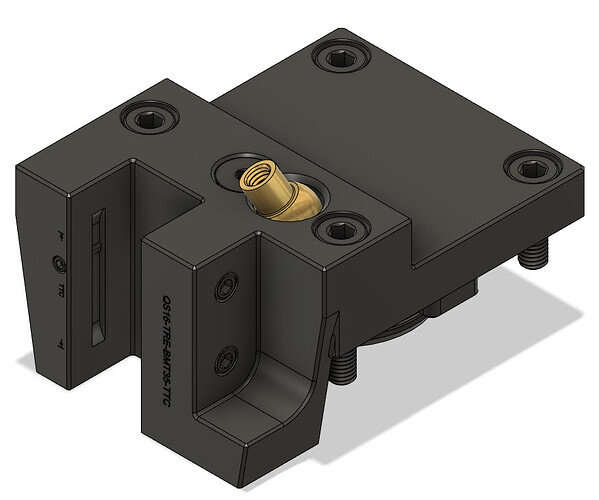

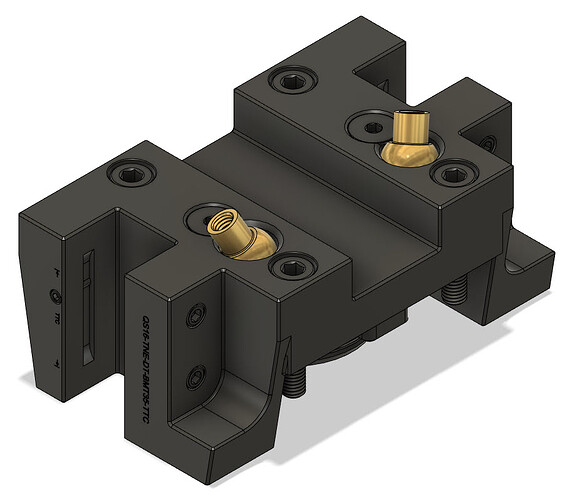

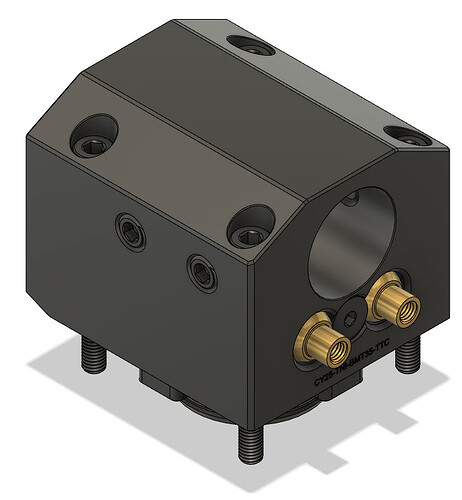

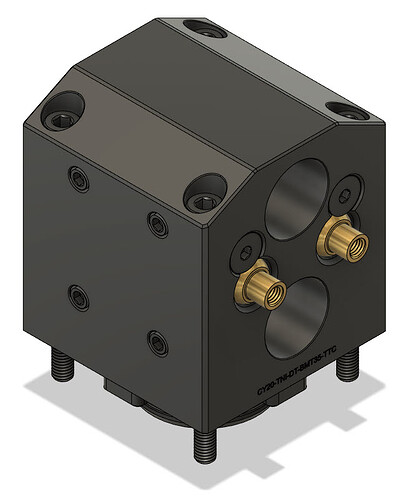

12 Station BMT style Turret for Clamp Modules that allow through tool coolant for 16mm Sq Shank Tools, 25mm Sleeves and Bars, 20mm Sleeves and Bars Dual Gang Holders etc…

Wireless Tool Setting

Parts Catcher

Bar Feeder for up to 1.5 meter bars with a 500mm long magazine tray

2 Likes

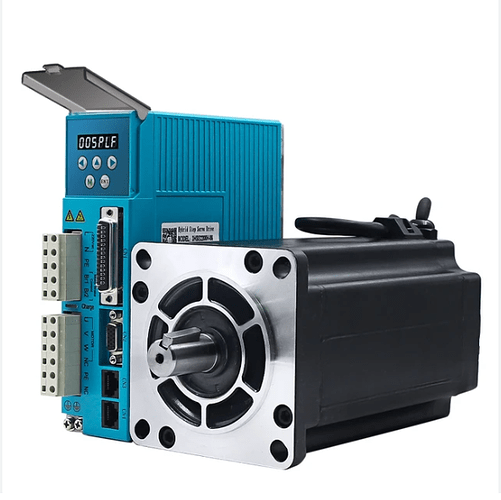

Only if it was servo driven like the 1500mx

2 Likes

The 12 tools is definitely a nice upgrade. Especially when doing small internal features needing multiple drills, boring tools and threading.

The sub spindle would be cool if designed with an upgrade path from the tailstock so a user can buy the machine with a tailstock then later add the Sub spindle if they desire.

The only other thing that would be really awesome is the ability to index the C axis and drill holes on a bolt circle.

Finally the bar feeder would be the absolute best freeing up the bar pulling operations and allowing the system to feed for longer periods of time.

1 Like

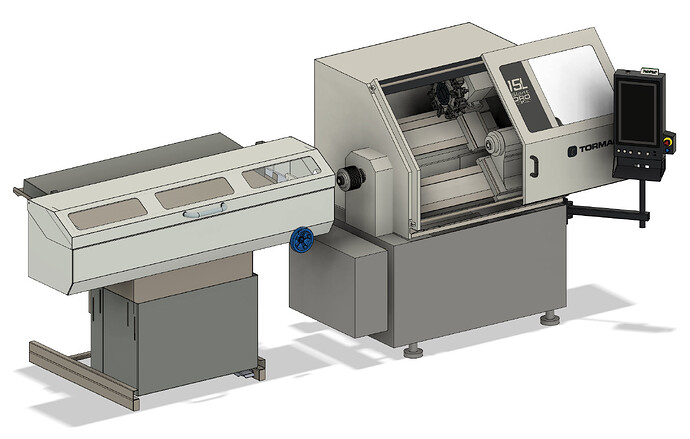

It would be good to see Tormach build an L & LX line of lathes to compliment their fantastic line of Mills.

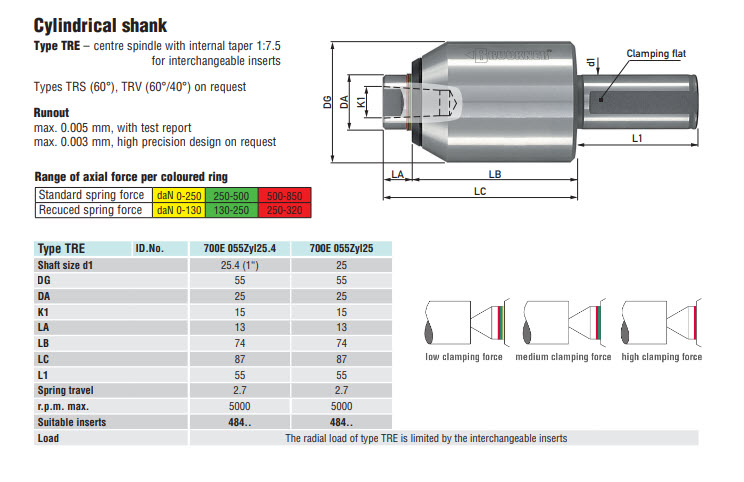

In regards to the Tailstock vs Upgradeable to Sub-spindle, I like the idea, but I also have to counter with Sub-spindle is also capable of being used in Tailstock application where parts pick up is not required.

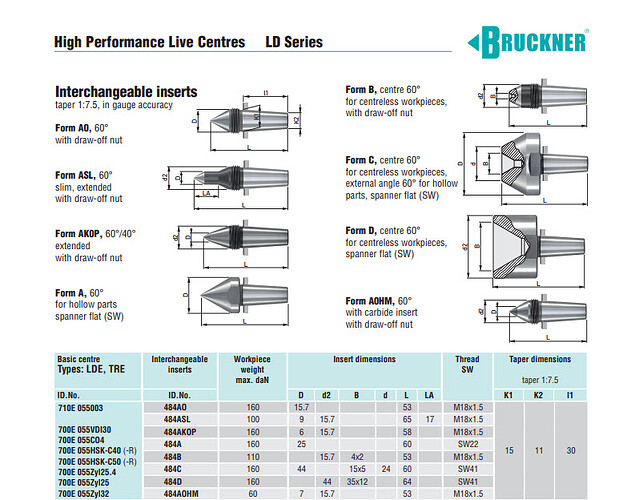

Below is an example of a Cylindrical shank compression type Live Centre that can be used in the sub-spindle converting it into a tailstock as required.

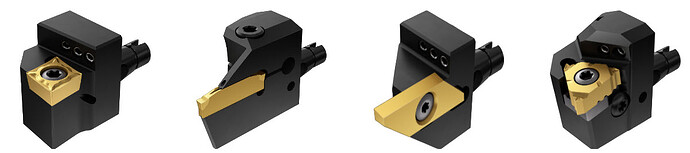

C-Axis and ability to Axial & Radial Milling Units would also be fantastic for basic cross drilling, pcd, keyways and splines. Anything more complex can be sub-operation in one of Tormach’s dedicated milling machines with 4-Axis or fixturing.

Features standard/optional I think are a must for a little bit bigger lathe:

Main Spindle:

- A2-5 Spindle Interface with 53mm through bore

- 6" Hydraulic chuck with 53mm through bore option

- 16C Collet Internal Drawtube and Closer Assembly option

- 5000-RPM Capable

Sub Spindle:

- A2-4 Spindle Interface with 38mm through bore

- 5" Hydraulic chuck with 38mm through bore option

- 5C Collet Dead-length Assembly option

- 5000-RPM Capable

12 Station BMT style or equivalent Turret:

-

At least 30 Bar coolant pressure

-

External Clamp Units in Left, Right and Twin Tool for 16mm Quick Change Through Coolant Shank Tools

-

Internal Clamp Units, single tool 25mm Bore, and gang tool options in 20mm & 16mm Bore

-

Axial & Radial Milling Units, at least ER16 would be preferable, not really sure what RPM would be a reasonable ask, but being small tools it needs to be high. If you go with a coolant driven design, you should be able to achieve very high RPM in a small package, only issue there becomes RPM adjustability because it is controlled by pressure.

Wireless Tool Setter

Parts Catcher

Bar Feeder:

- Capacity of up to 1.5 meter long bars with a 500mm wide magazine tray. (eg. 25mm round bar you could load x20 bars at 1.5 meters long for a total of 30 meters of material)

- Plastic Spindle Liners

Chip Conveyor:

I realise this is probably a really big ask/wish list, but it would be really good to see, and based on what Tormach has done with the 770MX, 1100MX and 1500MX, I am very confident Tormach are capable of delivering a very good feature rich and capable turning with live tools system.

This looks great! I wonder what the price range would be? That’s always the limiting factor for us - budget. Tormach has some fine machines, don’t get me wrong, but it was definitely the pricing that brought us to start looking at them.

1 Like

Yeah, looks good. 12 tools etc. The 15L isn’t a bad design, just needs a few tweaks. Longer bed to accommodate a tail stock that works. Servos that home well. Weight and size reduction on the turret. I have an earlier model and the manufacturing quality was lacking. I completely overhauled the lathe, turcite, spindle bearings, and sent the ball screws and nuts out for overhaul. I also had a local shop make a X gib for me as the other one didn’t qualify. Now I have a lathe that really hits the numbers. Homing is with dial indicators. Also upgraded to the X stepper with a brake, that really helps. I understand tolerances cost money but still. Also, any new upgraded parts lists should be emailed to customers so they know what’s the latest and greatest.

I also have a 770MX. Servos are much better. It could use a little more cast iron for dampening and rigidity. Spindle and head could use a little help too. But, these are entry level machines and don’t require 3 phase and weight 3 tons. A little more engineering and thought would go a long way. Maybe provide some component overhaul services. Room to expand…

A lot of companies out there are big on adding bells and whistles when they really should just be making the basic mechanics work well. Software is a great example.

One thing I really like is Pathpilot. Laid out pretty well. Easy to learn and use.

Overall I have enjoyed the using the machines and have learned a lot. Keeps me off the street corner. My two cents worth…

1 Like

Been thinking about a 15l for a while. Drawback for me isn’t the number of tools, its 12" Z travel. Would prefer something that will replace my 1440 manual. 30" would be ok. So probably a TL1 or TL2 instead, or upgrade my current lathe to cnc.

Dave

1 Like

Doosan ,Haas, Okuma, and Maxak already make those machines. I bought a 15L because it’s not 7000lbs. Competing with the big industrial machine manufacturers will put these machines out of reach for the hobby machinist.

Replacing a 1440 is a big ask, if you really look at the work you do on a CNC lathe typically 12" is sufficient, I too have a 1440 but to be honest you would grow the machine from a garage sized little production horse into a full fledged manufacturing facility footprint.

Also with the shorter length they could simply add 6" or 150mm of travel to make the space more usable but again if that prolongs the release of a new product I would hesitate and say lets make this machine faster and fix some of the low hanging fruit like Servos and Console upgrades. Then they can take some time to get an amazing Gen2/3 version that has all the bells and whistles.

Absolutely love this post, lots of great ideas.

1 Like

Did this for a living so I am used to larger manual machines . I fix farm parts for my brother in law so 1430 is about the smallest I would want for home. and would not need my manual then, It doesn’t take too long of a boring job to run out of room with only 12" in Z,

The TL 1 I was referring to is used. Most of the other machines I looked at have really old and some obsolete control systems. Though if good iron I could put acorn on. Would prefer PathPilot cause I used to it from my pnc 1100.

No interest in turning into a business. economic sense no, just want a new toy.

Dave

I upgraded mine with this servo stepper, they work great, I could do 200IPM, now with the new pathpilot update, I can’t alter the IPM anymore, I’m stuck at 100IPM. The X axis has one with a brake.

Can somebody tell me if there is a way to go back to 200IPM. Thanks, Jeff

Sign me up for a Tormach lathe like this. 51mm min through bore, 500mm z travel (or better yet, 600mm), and tailstock are the non negotiable requirements. An epoxy granite frame and rails /servos like the 1500mx and similar power would be the icing on the cake.