@cushmaca - sorry we missed your reply a few days ago on this thread. I see you posted that DXF.

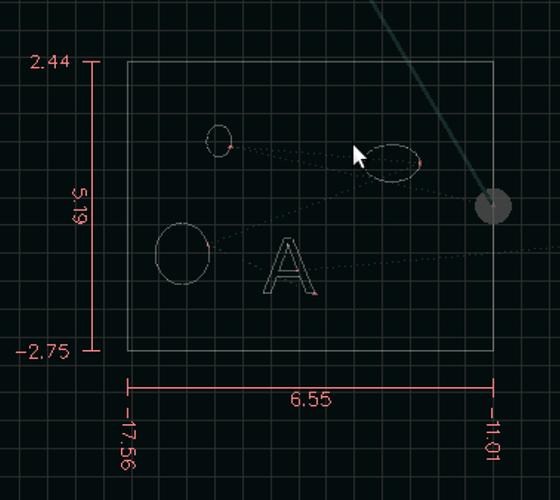

I loaded it and ran it and the way it behaved was exactly as I expected it to behave.

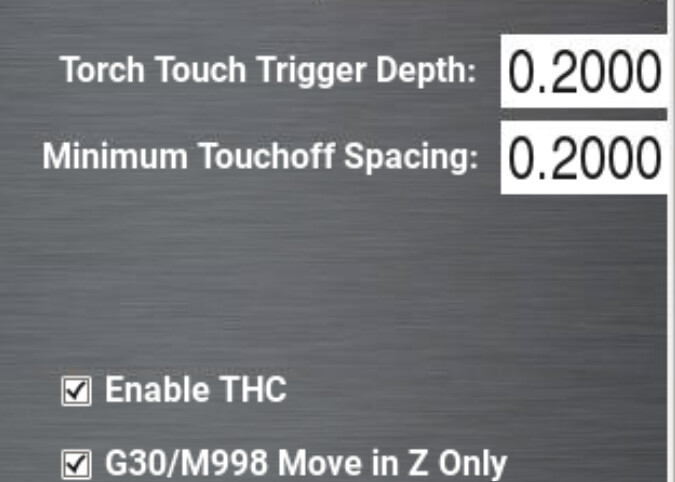

It probes the workpiece (using either ohmic probing or microswitch touchoff, explained in this video) before starting every new shape. I think that this is what you’re asking about when you say “if its a flat piece of work why raise up and not continue cut with just x,y movements.”

If you don’t like this, it’s easy to to change on the settings tab by entering a larger value in the Minimum Touchoff Spacing DRO (see page 46 of our user manual for details).

If you mean instead "why doesn’t it just keep cutting between the shapes" the answer is that it hasn’t been programmed to do so. Our DXF import utility doesn’t know whether you want to keep the shapes themselves or the material from which the shapes were cut (which is more common in sign-making like. this post). If you wanted the latter, you’d end up with a bunch of nasty cuts through your finished part and you’d be spending a lot more in consumables. If you only want the inside bits, and you want it to keep cutting, you’ll need to use CAD/CAM to create the toolpaths.