Hi all,

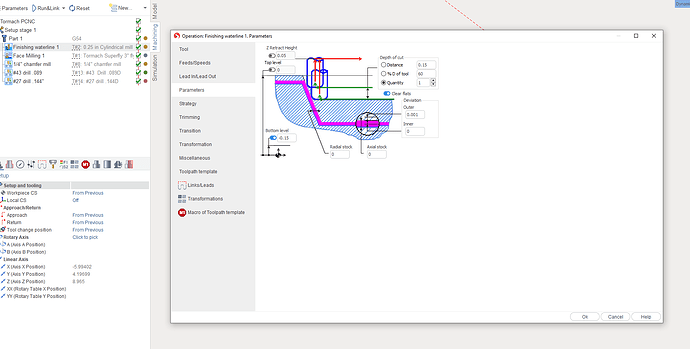

I have been working on some parts on my mill. I’m assuming there is an easy answer to this question. I have had a problem setting the depth in parameters. When I’m doing a milling path around the part I get this in parameters.

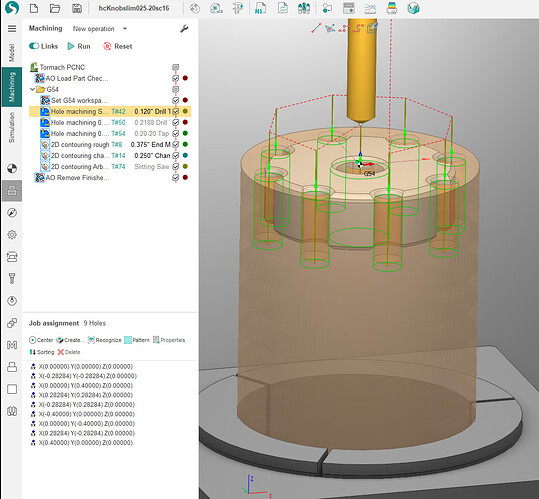

But if I am doing a drilling operation I get this one and can’t set a drilling depth.

Is there some setting that I have set wrong?

Art

Oh Yeah, I’m Using SprutCam 15

Art

You need to set the depth and location of hole to be drilled in the job assignment tab.

First select holes and add them to the job “this can be done a number of ways”

It should look like picture below.

Then click on the hole green lines to select it.

the diameter and depth will show up on screen like picture below.

you can set the depth 3+ ways

- job assignment , select hole and the select properties button

- job assignment, select hole on screen and change the depth numbers shown.

- Job assignment, select hole on screen click on bottom circle and drag up and down to desired depth.

- Sprutcam will recognize holes and add them to job assignment with depth set as per your model.

Hole machining is one of Sprutcams oldest and most refined operations. Read the way of the hole in the Sprutcam user manual  BTW this is sprut 16 but only change is the tabs are down the side not across the top of the small window

BTW this is sprut 16 but only change is the tabs are down the side not across the top of the small window

Takes time to master and navigate Sprutcam or any high end cam. There are a dozen ways to do about anything and 10’s to 100’s of settings for any one operation

2 Likes

Lane,

Thanks, I’m not very adept using SC, Mostly repeat what I know & when I can’t I’m out of my depth. It was helpful to be able to type in where I want the hole to start and end. My experience with the help section of SC is that subject not found, such as a circular pocket. Use the wrong terminology and not found, and it highlights your key word in blue which I find distracting and annoying. I would love to do this part as G54-G55 but even after watching Jacobs video on flipping a part I get frustrated & give up. is there a source of info, tutorial ect. that covers this & other subjects better. Or the toolpath templates How does someone like myself whose background Isn’t in cnc know what I can delete from the template? Sorry for dumping all this but I realize there are 100’s of these little tricks like you just showed me that I’m clueless about.

Art

Sprutcam takes time to learn. It is a very complex program to navigate.

I had extensive CAD experience and also started at zero with no CAM or CNC experience.

Back then you were on your own. Only real way to learn was to set there drawing and loading models and then set up offsets, fixtures, tools and operations. Then run and simulate, then change settings and run and simulate more… Then compile g-code and go to machine and run it with offsets set in the AIR to be safe. If ok then cut parts. With experience and confidence you know the programs are good  and then you can skip air testing and go to cutting.

and then you can skip air testing and go to cutting.

Over time you learn what you need and refine that into very complex setups that can have multi sided multi offset parts with dozens of operations on each side and good g-code ready for the machine with little or no drama to make a part. “all in one file” if you want!

Maybe watch more YouTube videos that are done by Sprutcam. I think they still have them posted on the Sprutcam site also. All I can say is have hundreds of hours into learning the program and making it work for me.

1 Like

You might want to consider upgrading to SC17 or even the new EncyCAM, which is replacing the SprutCAM product line. I started with SprutCAM 4 and have been upgrading as each new release comes out and it seems to me the the product has gotten easier to use (and more consistent) with each new release. Or maybe I’ve just starting thinking more like SprutCAM.

1 Like