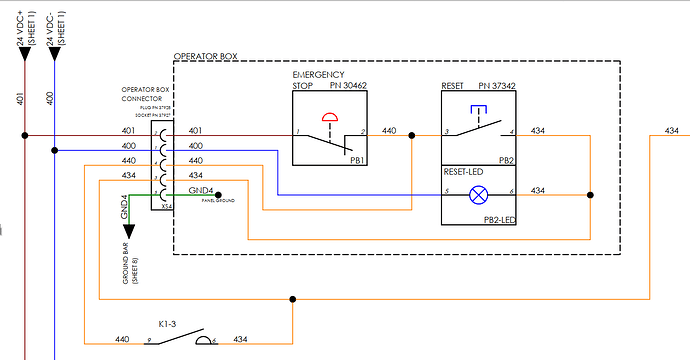

I am looking to install a second e-stop to my 1100m that will be placed in another area of our shop for safety reasons. I have the operator console for the machine, but I couldn’t find any documentation on where to integrate this second e-stop.

I doubt you’ll find documentation on this as it’s not a common thing. That said, it should be fairly easy, though it would require some hacking. The E-stop itself is a simple on/off switch. Buy another one from pretty much anywhere and wire it in series with the existing one. That way, either of the buttons being pressed will cause the machine to stop.

Estops typically use a normally closed switch but I can’t say for certain if that’s whats on the machine currently so you’ll want to verify that before buying anything.

Also, bear in mind that the circuit running the estop is fairly low voltage (not sure if it’s 5 or 24vdc) so depending on how far away you plan to put it, you may run into issues of wire length creating too much resistance and causing problems.

Ian,

I think you meant to say to wire the second E-stop in parallel (not in series) with the existing one. I did this with my old 1100 so I would have easy access to it since my machine is in the corner of a crowded shop, and the original switch isn’t easy to get to in a hurry. - Terry

I did not think about the voltage drop; we were looking to put the E-Stop about 50 feet away. I hoped there was an easy place to plug it into the controllers in the back of the machine. The current E-Stop is integrated into the operator console panel and not easily accessible.

Nope, definitely meant series but it does depend on whether the contacts are NO or NC.

Parallel works if the switch contacts are NO because hitting either would make a connection and send power to the controller.

With NC contacts, parallel wiring would require both buttons to be pressed or one of them will still be sending power even when the other is not so the controller won’t know anything has changed. In that case, series wiring is needed so that hitting either button breaks the connection.

@Matthew_Dunster, 50 would be fine, I only mentioned distance and voltage drop because I didn’t know how far you had planned to run the wiring. To my knowledge there is no secondary e-stop plugin location anywhere on the machine. Without the op console the button is in it’s own little box and very easy to get to. With the console, I image you will have little choice but to open up the console to get at the wiring behing the button.

IIRC the console has an ‘extension cable’ that plugs in where the control box used to connect. Should be able to access the wires there. Many ESTOPs are wired NC so any break in the circuit (cut wire, loose, disconnected, etc) causes a stop.