We’re going to try copying a Schlage SC1 key, you’ll need to have purchased a blank or two. Some hardware stores that duplicate keys may sell you uncut blanks, but often times you’ll need to buy them online.

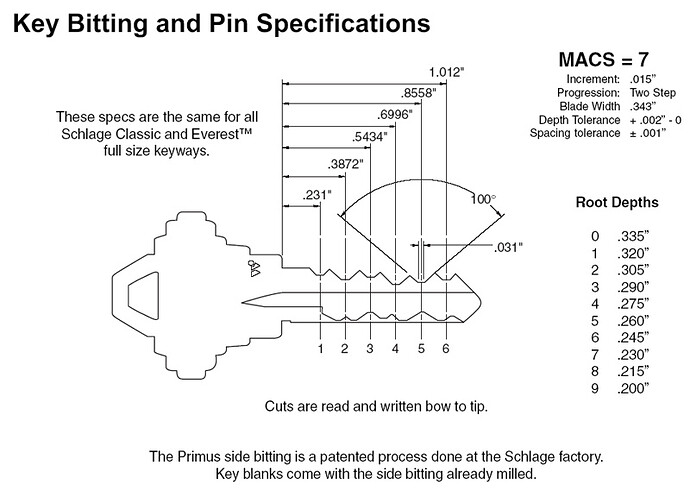

Having a blank removes the difficult part – the key profile. This means we just need to cut down the bitting profile along the top of the key. Fortunately there is a lot of discussion online about common key bitting, mostly meaning Kwikset and Schlage locks (which I almost guarantee is opening your front door at home). You can find an OpenSCAD script which will allow you to turn a key code into a 3D model. Unfortunately the easiest way to handle cutting the key is typically orienting the key vertically, but we’re going to give it a shot sideways and use a small file for a little cleanup afterwards. The truly proper way to cut this key is to use a slit saw and a key held vertically just like a regular keycutting machine would, but that doesn’t sound like hacking to me!

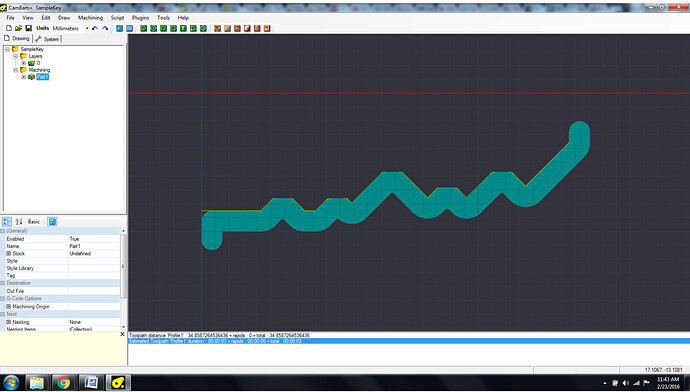

I’m going to use CamBam to generate the gcode for this example. CamBam will only take a DXF file, the catch is our OpenSCAD file is in 3D as an STL natively so we need to slice it up into a 2D line.

One we have the key profile, we open it in CamBam and check to see how well we can match the profile with a 1/16” cutter.

(You can turn on the tool cut path in View->Show Cut Widths)

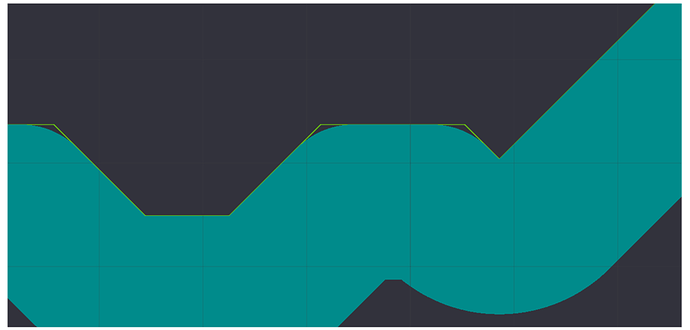

I don’t think we’ll have any trouble opening a lock with this match up:

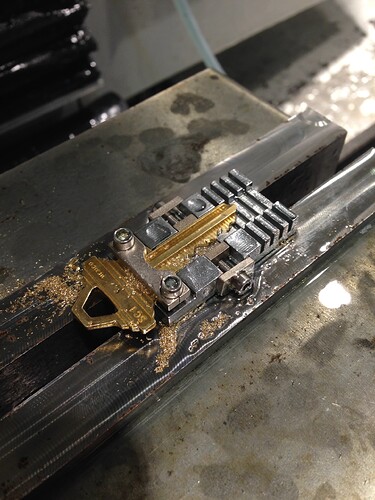

The next challenge is figuring out how to fixture the tool. In my case I felt it was easiest to cut a shoulder step into a block of aluminum and use a t-slot clamp to hold the key in place against the block. You can certainly devise a better system. I ended up buying a key holding clamp:

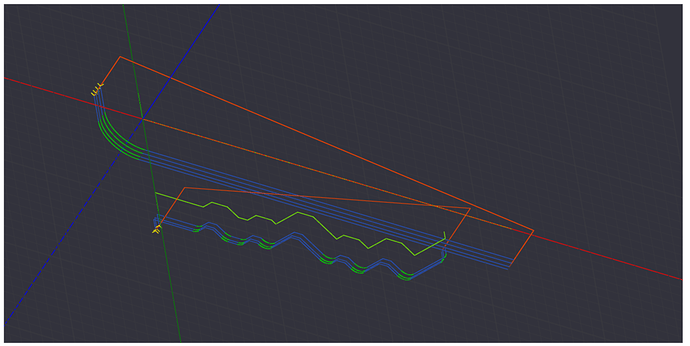

We need to create the path to cut the steps in the vise, in this case I made them in the same CamBam file so we wouldn’t have to indicate the key location after cutting the shoulder. You can see the green arc at the upper left below that shows the origin cut path. Then the key is cut starting at 1mm working down to 2mm with a 1/16” bit since the key blank is pre-cut to partial depth there’s no point wasting time cutting air.

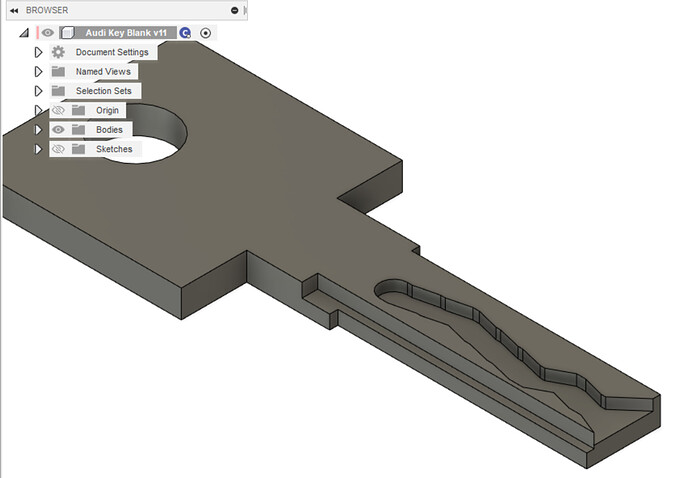

I’ve also successfully cut an Audi/VW style “laser cut” key with the side bitting on both side of the key:

https://a360.co/3dPnec0

using Fusion360 from a piece of aluminum. I had a single key for an Audi and the only way to add a new one was to have one in the ignition AND one in the door at the same time and swap the ignition key with the replacements to teach the security system so I needed a stand-in for the door key ![]()