Hello all,

I’m trying to set up a 3rd-party tool setter on my 1500mx.

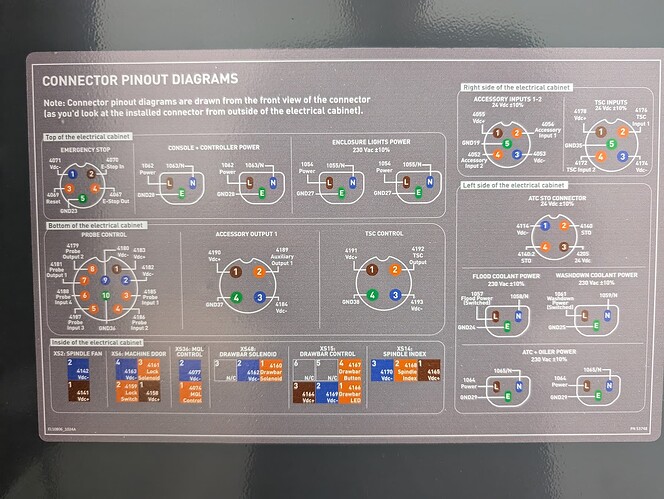

The 1500mx manual says to wire an ETS into the Accessory 2 port. But I think that may be left over from other Tormach models. I don’t have a separate accessory 2 port on my 1500MX, only one accessory input port with 2 input wires in it, and those don’t seem to do anything with the ETS.

I read through the install for the 1500mx wireless probe and tool setter package, (which I don’t have as it was expensive, and I don’t need a probe, just a tool setter). The receiver for that plugs into the “probe control” port. After some experimenting, I wired my ETS to “probe input 3” in that port, and set it to pull the input down to 0vdc when the tool setter is pressed. This makes the “ETS input” indicator on the “ETS setup” screen turn from off, to red, whenever the ETS is touched. So I thought I was close there.

However, if I try to use the “ETS spindle Reference” button, I get an error “Probe not ready within 10.00 seconds”. I’m guessing it needs to see that the wireless receiver is active on the other inputs. I’m open to jumping those inputs if possible, but the timeout makes it seem like there may be some active communication happening there.

I’m completely new to both Path Pilot and using an ETS, so I might be missing something simple here. Any suggestions for getting a basic, wired, one-input tool setter working on the 1500MX?

Thanks for reading!