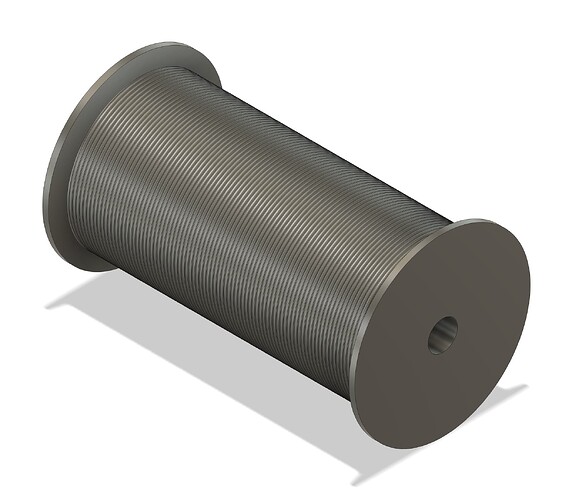

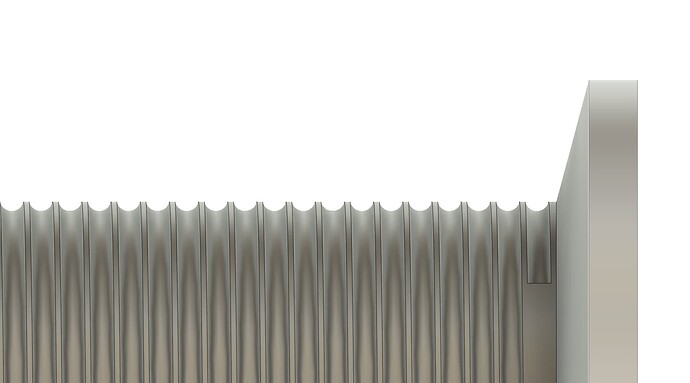

I’d like to machine this winch drum. It’s 100 mm long, 50 mm in diameter (the drum face). There is a spiral groove designed to help guide the cable that will wind onto it. Do you think this is something that the 15L can machine? How might I do it? I think the typical threading operation would crash into the side walls.

I’m using Fusion, but haven’t explored whether or not it can make a tool path for this. I don’t care too much about the exact thread profile. It’s modeled as a circular arc.

I did something like that several years ago but it engaged like regular threading. The 15L conversational works pretty well. Set your pitch in a decimal number and it will do whatever. I used a radiused grooving tool. Side and front reliefs were not exactly great but it worked with quite a few passes. I don’t use fusion so i can’t help there. May have to model something and see what i can come up with.

Maybe 3 pieces?

1 Like

Without a C axis, you pretty much have to do it as a thread which would be fine except the threading cycle starts off the part in Z, waits for the spindle to come up to speed, waits for the pulse from the spindle position sensor, then leads in along Z at a constant X value. Without playing with it I don’t know if fusion will allow you to alter the lead in to also have an X component but I suspect not. You definitely can’t use a canned threading cycle since they will all move in along a straight Z path.

If it were me I’d be looking at two options, either turn the basic shape on the lathe, then stick it in my 4th axis and mill the groove with a ball end mill (if you have a mill and a 4th of course). Or, make one of the flared ends a separate piece that threads into the rest of the part. That would allow you to run a simple thread cycle without crashing into the part.

2 Likes