I was looking for a G71 breakdown. I found one, but not PathPilot so the variables were incorrect.

On Tormach’s site there is a g-code list but G71 is not on it.

G71 P1294 D0.0200 F0.0050 J0.0060 L6 I0.0030 K0.0030 R0.0200 E0

Can anyone define this.

P not sure.

D is depth of cuts

F is feed rate

J, I and K unknow - if there were only 2 I would think that is stock to leave on X and Z

L is the number of times to repeat the cut.

R is the retract amount

E is anyone’s guess.

I don’t mind manually programing, but not if I have to guess.

First I would highly recommend the book “cnc programing” by Peter Smid

I could not live without it. While it does not always apply to Tormach and Path

pilot machines it is what I consider a industry standard. And if possible most code developers should follow it if possible.

from page 326

G71 cycle format 6t/10t/11t/15t

The one block format for g71 cycle is

G71 P… Q… I… K… U… W… D… F… S…

P = First block number of finishing contour

Q = Last block number of finishing contour

I = Distance and direction of rough semifinishing in the x axis per side

K = Distance and direction of rough semifinishing in the z axis

U = stock amount for the x axis diameter

w = stock left for finishing on the z axis

D = depth of roughing cut

F = Cutting feed rate (in/ rev or mm/ rev) overrides feedrate between p block and q block

S = Spindle speed (ft/min or m /min) overrides spindle speeds between P block and q block

I and k parameters are not available on all machines

G71 Cycle format 0T/16T/18T/20T/21T

If control requires a double block the format is

G71 U… R…

G71 P… Q… U… W… F… S…

first block

U = Depth of roughing cut

R = Amount of retract from each cut

second block

P = First block number of the finishing contour

Q = Last block number of the finishing contour

U = Stock amount for finishing on the x axis diameter

W = stock left for the finishing on the z axis

F = cutting feedrate overrides “same as noted above”

S = Spindle speed “same as noted above”

This gives you the cnc standard but might require tweaking in format for Pp to read correctly.

The book goes on to give examples in both internal and external roughing examples!

Hope this helps. And buy the above book its the best reference I have ever found period!

All moves in G71 and G72 have to be in the same direction. No Z positive moves and no X positive moves above the X value of the initial point. The P block will be your first feed rate move on the first cut. The Q block is the last fed cut to depth. The cycle will always start and end at the initial point. That is the X,Z position before the P block. The code between the P and Q blocks is considered the finish pass definition. All material will be removed from a box created by the initial point and the geometry defined in the finish pass definition. Any material left in the G71 command will be taken by a G70 line using the same PQ block geometry after the G71 cycle.

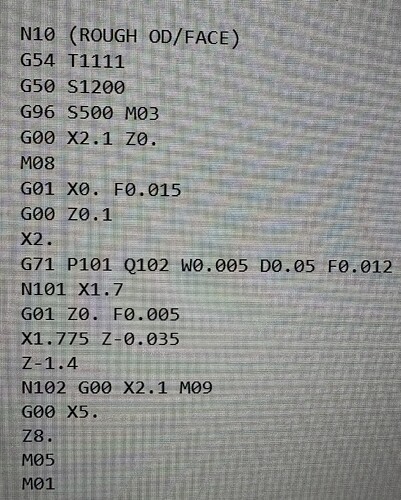

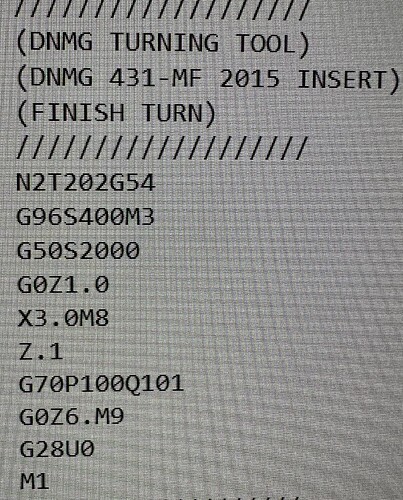

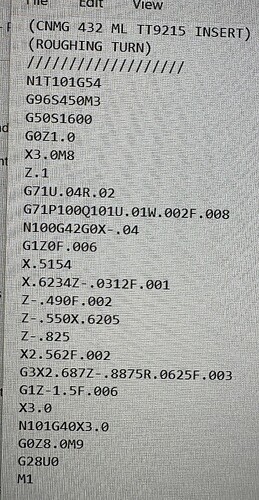

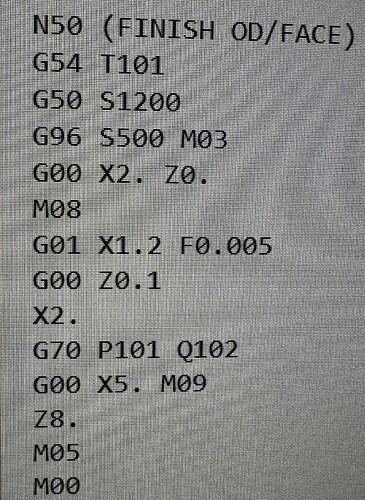

Examples of single line (from a Haas) and double line (from a fanuc control on a doosan

) and their finish passes

1 Like