Has anyone found a workaround for the Error that occurs when changing tools during a mult-Tool program? While running a multi-tool program, the program halts and awaits the tool change. The tool is changed, the enclosure door is closed and the ‘Cycle Start’ button is pushed. IF the button is pushed before approximately 3 seconds after closing the enclosure door, a VFD Faulted Error occurs and a Reset and REF X and REF Z is required. I have found that counting one-thousand one, one-thousand two, one-thousand three solves the problem, but that is absurd and I should not have to wait. The problem appears to be in the PathPilot program, since when the enclosure door is opened during a program, the spindle breaks within 100 milliseconds or so and the program waits for the door to close and the Cycle Start to be pressed to resume, so the proximity switch circuit is fast enough. The PathPilot software is apparently not polling the status of the enclosure door often enough when it expects the door to be open during the tool change. If anyone has written a python script to correct this, I would certainly appreciate it.

You might want to double check with someone at Tormach but mine did the same thing. They said it was common for the left side spindle door and the main doors micro switch to be switched around. So when your opening the door to switch tools it thinks your opening the spindle door.

If you remove the rear panel and look at the upper right corner you can see the two micro switches side by side(they are kind of tucked in there)It’s a little tricky to reach around to swap them but it can be done by your self.

I know it’s frustrating especially while running parts but when I called Tormach about it they where great at talking me through it and stayed on the line till I had it fixed ![]()

Good afternoon Jeff!

I tend to agree with @Chris_Zajic on this one, with the swapped switches. I would say we should make a case on this on, and Craig will try and confirm if this is indeed the issue! You can open a support ticket, here.

I have debugged the situation and proved to myself that the switches are backwards since there is no delay required when closing the spindle door and pressing the Cycle Start button immediately. I’ll open up the electrical panel tomorrow and swap them.

I started having a problem with the door on motor side after machine had been used for a couple hours. It would fault and cause the vfd to not restart the motor. Didn’t matter if it was mid program tool change or opening the door to release collet and reposition stock for next part. When machine was warm it would fault out and require complete shut down for as much as an hour to fix. I traced the problem to the hal switches on both doors and just bypassed them all together with small magnets over each one. No safety shut down of motor when doors are open but that is not a problem for me. Also it allows me to open door clean chips while machine is running if required. This is not a Tormach solution safety wise, but it works fine for me. I often wondered if my machine was the only one until now.

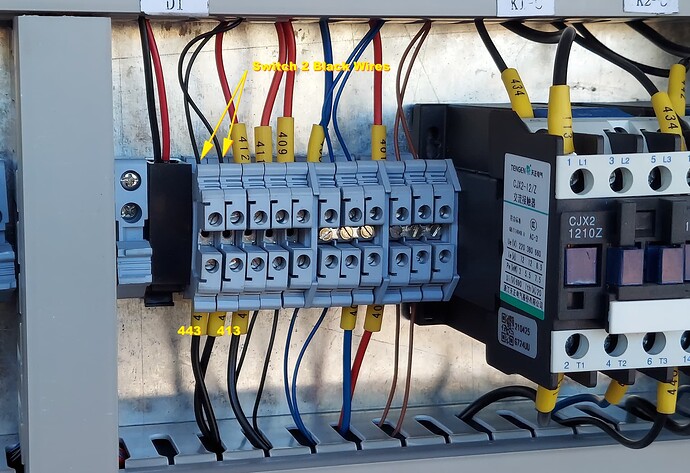

The solution to the reversed proximity switches is easy! I always want to know how things work, so I opened the Electric Panel door and started fishing into the wiring and following the grey switch leads. Unlike the solution that Tormach gave @Chris_Zajic described in a previous post (swapping the physical switches required), I found that swapping two wires solves the problem. The output of the NPN Proximity switches for the doors need to be swapped, so find the black wires labeled 413 and 443 on the short buss strip between D1 and K1 and swap the small 26 gauge black wires coming in from the top (the outputs of the switches - electrical schematic sheet 6 labeled 413 and 443). Since the +24 volt and Common leads (brown and blue wires) are in parallel on the buss strip, they do not need to be touched.