I am trying to cut internal metric 22x3 acme threads, of course LH, on the 8L. I have the appropriate cutter but I dont see anywhere in conversational where I can set the machine up to do that specific task.

Did you try typing G21 to change to metric mode.

Not sure that will work but that’s what I do on my mill.

Oh yeah I can change to metric but the trapezoidal form is causing me issues

Multiply the metric lead by .03937. This converts it to imperial. Hand input that into the lead column in path pilot.

What would that have to do with cutting 30 degree metric trapezoidal

threads?

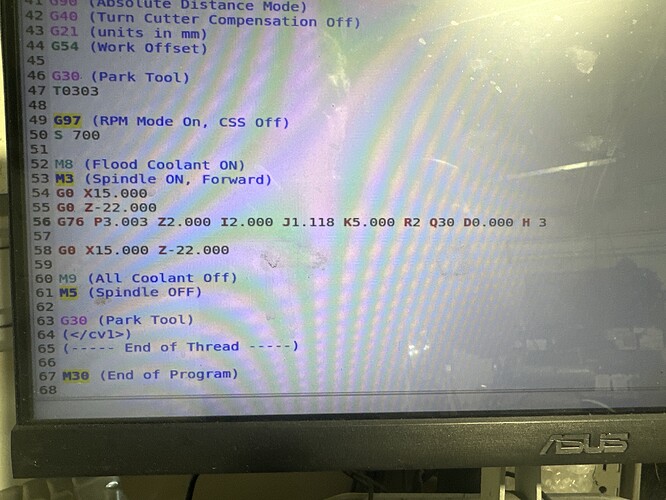

Our machine unfortunately does not support turning multi-start threads, but I wanted to let you know that I will add this to our feature request list.

Trapezoidal/acme threads are not multi start

My apologies, I had thought that by 22x3, you had meant you wanted multiple starts. In that case I would agree with the above post to switch the machine to metric and type the thread data. When you say that the trapezoid form is giving you problems, what kind of issues are you experiencing? I understand from my experience machining that Acme threads are tricky and require playing with the offsets and number of passes a bit more than other more standard thread types, but the procedure for writing a conversational program would still be similar.

As a side note, after making the comment that PathPilot does not support multi-start threads, a co-worker showed me this work-around we discovered that I wanted to share for anyone paying attention to this thread: Multi-Start Thread cutting in Conversational - Lathe - Tormach Forums

That converts the metric lead to an imperial lead so that you don’t have to put the machine in metric mode. On the posted can cycle there will be an A60 or A30 some other letter with 60 or 30. If it is 60 change it to 30. If it is 30 change it to 15. That tells the machine the angle at which to feed the thread into at an angle to cut instead of form the thread. I do believe acmes are something like 24 degrees.

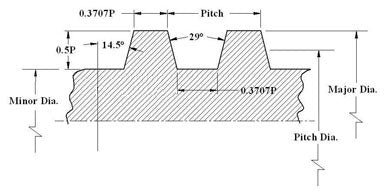

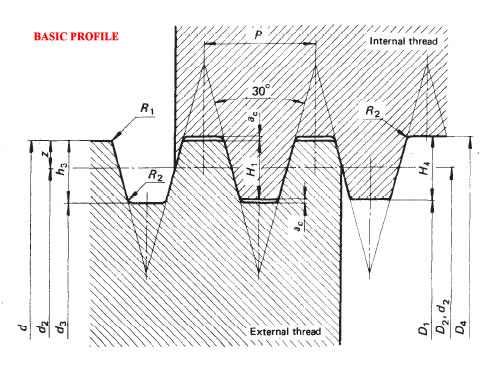

Metric trapezoidal are 30 degrees. Im trying to cut a internal 22X3 MM LH metric trapezoidal. I have metric trapezoidal cutters.

Theyre often referred to as metric acme but theyre not really acme.

I see now. If you are using a canned cycle that is set for a 60 degree v thread it will not work out. Have you changed the thread cycle to cut a 30 degree included angle thread?

No, because I dont know how to do that on the 8L. That is what I am asking

I went to my actual computer instead of my phone. The information originally here was incorrect and I am not sure how to delete it.

G76 X2.775 Z-1.57 I-0.105 K0.1 D0.005 A60 F0.125

G00 X8.

Here is a g76 from a Haas lathe. It uses an A60.

G76 X, Z, I, K, D, A, F;

- X = Minor dia of thread

- Z = End point of thread

- I = Taper

- K = Depth of thread

- D = Depth of first pass

- A = Angle of thread

- F = Pitch of thread

Here is the breakdown of a fanuc single line threading cycle. It also uses an A. Add A30. to your g76 and see if that is it.

Exactly. You will have to add A30. To the G76 line for the machine to infeed at the proper angle.

Are you sure about the A parameter?

https://linuxcnc.org/docs/stable/html/gcode/g-code.html#gcode:g76

Q- - The compound slide angle is the angle (in degrees) describing to what extent successive passes should be offset along the drive line. This is used to cause one side of the tool to remove more material than the other. A positive Q value causes the leading edge of the tool to cut more heavily. Typical values are 29, 29.5 or 30.

I tried changing the Q value to 15 thinking the same thing you are . No dice. I get about half way through the threading operation and have to stop and chase it with a tap. Made no difference.

I really need this to work and wish Tormach had better support for their product and software.