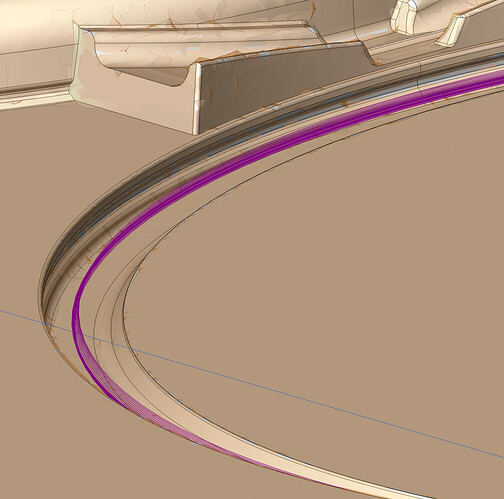

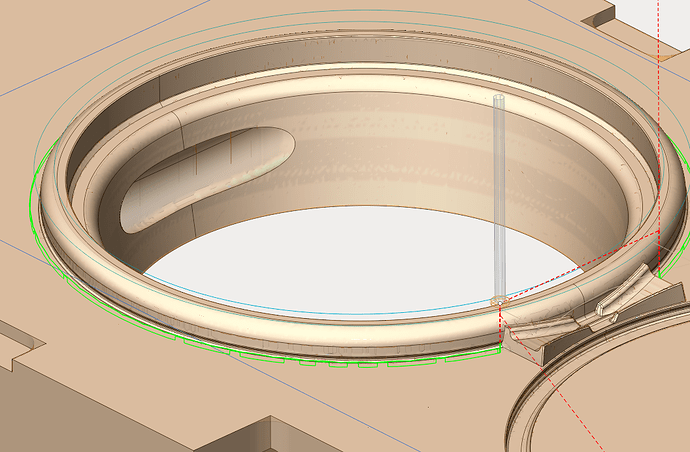

The bottom image shows the toolpath whether I try to use 5D contour or 5D surfacing. Just can’t get it to work. In the upper image with the violet toolpath 5D contouring worked just fine. Can’t figure out what I’m doing wrong here. The groove is a radiused groove with a tapered slope on the bottom. Needs to be cut as exact as possible. Suggestions?

Could be a long list of reasons that would need to be checked or eliminated!

Why 5d contour? Looks like a standard 3 axis operation will do the job.

Cutter is defined in a way Sprutcam detects a collision and wont generate a tool path!

Cutter cant reach the area required to be milled without gouge. Again no tool paths will be generated.

I would check how the cutting tool is defined and try different CAM defined test cutters that are smaller or defined and known to work on similar operations.

I could type reasons for another 30 minutes.

Sorry cant help much only a few guesses on normal problems. Need more info

L.A.

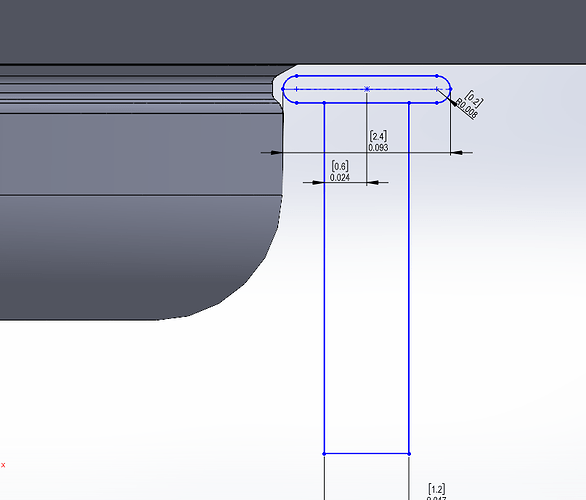

Image: Undercut profile with cutter outline. should reach ok. This same cutter definition using 5D Contour did what I needed on another part with a very similar undercut. Paths usually generated even with gouging (which then shows in red and marks an alert). Is there another operation that might cut this? Very few allow use of undercut mills. I will check the definition over again.

Tool profile picture looks fine. You need to look closely at the tool as defined in tool table and shown in the simulation window… I found version x-16 has some quirks in tool definition that worked fine in version 15 but cause errors and problems in version 16. Also if you select the surfaces to be milled and click surface in job selection it will help sprutcam understand what your doing. Another option is to define a line inside that feature at the surface of it. tgen use a 2d operation to mill to that line or lines with the undercut cutter. you will need to control the approach and return and depth of each pass to get at the inside radius. Sometimes you just have to experiment with operations and settings and job selection of surfaces or lines until you get the correct results in the simulation. in short you can do it. just might take some time to figure out a way!