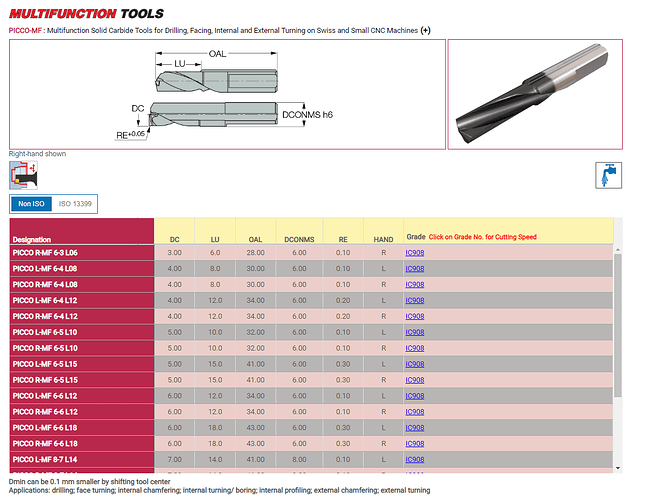

I keep one of these Iscar Picco MF tools in my turret all the time. Being able to drill and bore and turn with one tool is awesome for prototypes and short runs and just not having to use 2 locations (or more). So far I used it in Aluminum, Delrin, Steel, brass/bronze and Stainless. I have used it in 303 stainless doing 800pcs runs too. They offer a special holder, but I made my own out of 4140. The tool seems quite happy at the sfm and feed rates of the slant pro and I think it would do well in the 8L as well. They don’t give them away, but if you get paid for your work it doesn’t take much to make up the money in time savings.

These are pretty neat tools, there’s a variation that can thread, too. We used them in the lathe class that we had run a while back. $80 a pop stings a bit, though.

Thank you,

Norman

An inserted U drill will do the same if you align the outside insert to be on centerline with the the X axis travel

I have been looking at those for larger holes.

If you keep it inside the turret, how do you config both controls points to be drill and boring at the same time?

I set up tool 3 in the turret as a boring bar. I did my test cut to set the tool offsets, then I created a tool that I numbered 33 and used the same z offset as 3 and shifted the x so that the centerline of the tool would be at x0. If I need to use tool 33 I hand code a T0303 before to make sure the turret is in the correct position. In practice I haven’t used tool 33 in quite some time. As long as the desired hole dia is larger than the cutting dia of the tool, I just use ID TURN or PROFILE internal and the Picco can just plunge where a boring bar could not. Its possible Fusion could handle the tool as 1, but I haven’t tried it.