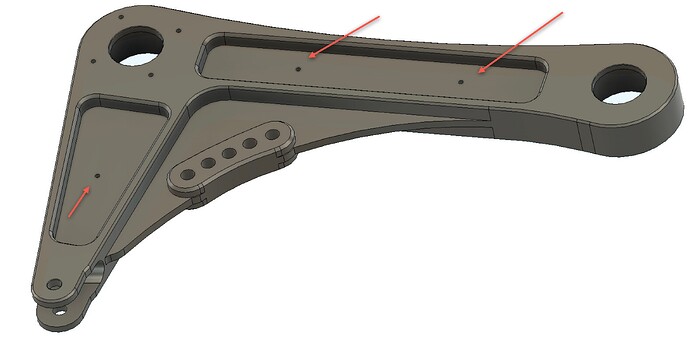

I am not yet to the point where I am ready to try to machine this but I am thinking about workholding strategies. I have a SMW fixture plate on the machine with 2 mod vises. It seems like securing it on top of a sacrificial piece for ops 1 & 2 are my best ideas so far. How would you do it? I’ll post a link to the 3D model if you want to roll it around. Fusion

Thanks!

@Scott_Dube Are you cutting this out square stock? If so you could always drill out and use some of the bores, and bolt the part into a fixture with some shoulder bolts for accuracy. Not sure what you’re looking at quantity wise, but this would always be an option. Not sure what dimensions are critical, which aren’t.

Sam, I have a piece of 12x24x1 AL stock to cut this from. I can leave it that way or cut it. I think from a stock-saving perspective leaving it would be better. The critical dimensions are the 2 large inside bores as they will each hold a bearing. This is currently a one-off project but there’s always the possibility of more. For now, it’s a prototype.

If it’s a prototype, it may be a bit overkill to make a fixture plate specific for the job. But it’s an option, have a tight tolerance bores to hold and locate the part accurately would be pretty dang convenient. I would be interested to hear others opinions. I’m sure soft jaws are always an option as well.

I’m starting to think I could drill the holes in the picture larger and then bolt down through those. I would have to use toe clamps, to begin with, to machine those holes. They’d also have to align with the SMW fixture plate which might be a challenge. Also, I’m not sure if you noticed the large bores are not the same all the way through.

Why not just bolt it to the table at two points of the stock that are not used.

Harold,

I would recommend against that. That is how you punch a hole in the table.

Thank you,

Norman

1 Like

Thats fine for the first side but once you flip it over you have to be on the part with the work holding.

Since I have the SMW fixture plate I’m thinking about dowel pins to locate the stock with tabs for 2 sided milling then once I’m done I could secure it through the bores and use a contour to mill off the tabs. What do you think of that?

TIA