So I have cut my first parts on my new lathe! I have a couple of things that might save new users a little trouble.

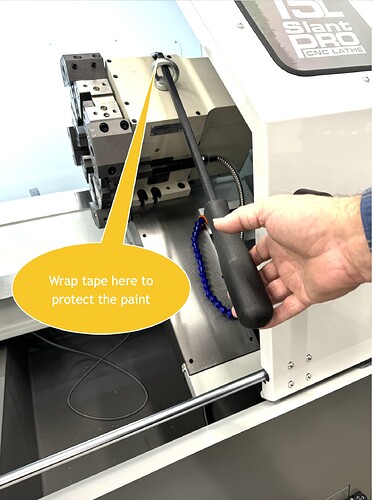

First when it comes to assembly the turret is very heavy and in order to align it they recommend just pushing on it to be able to slide shims under it. I found that impossible for me but I did find that by using a pry bar with some tape on it (to protect the paint) through the lifting eye. This made it very easy and controllable while sliding these shims under the turret. You can use the bar in both directions depending on which side you are shimming.

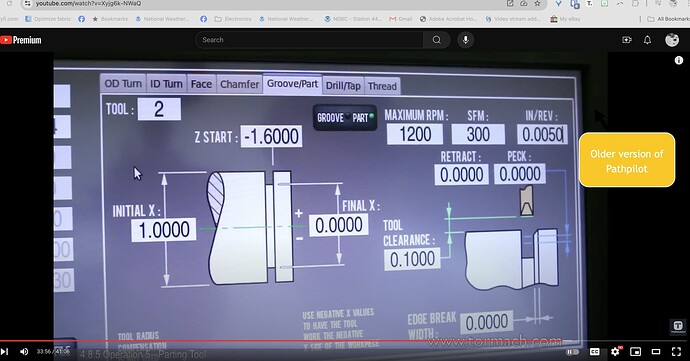

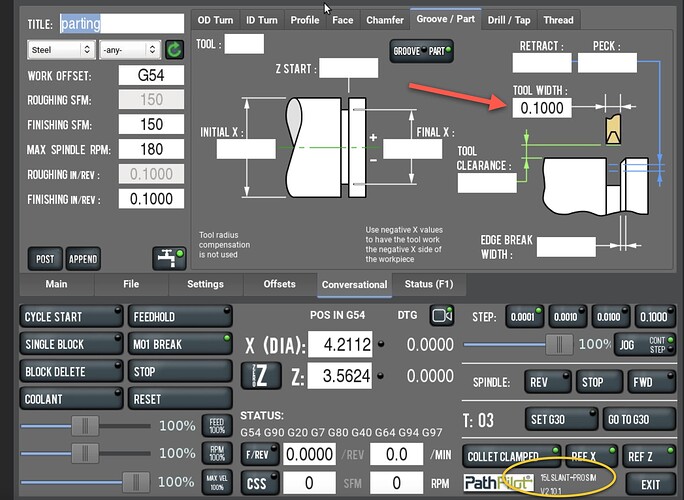

The other thing I found was that the videos put out by Tormach and the manual with the lathe need to be updated to reflect a software change (I think). If you create the first part as the video and manual outline you will end up with a part that is too long by the width of your parting tool. The problem I believe is that these two resources lead you to believe you need to add the thickness of your parting tool when touching it off. I think the problem is that was before it was possible to add tool width in the conversational parting screen. See the next two screenshots.

Hope these things help let me know if you think I’m wrong. I’m also wondering how this tool needs to be touched off if the code is created by an external CAM software.

Scott