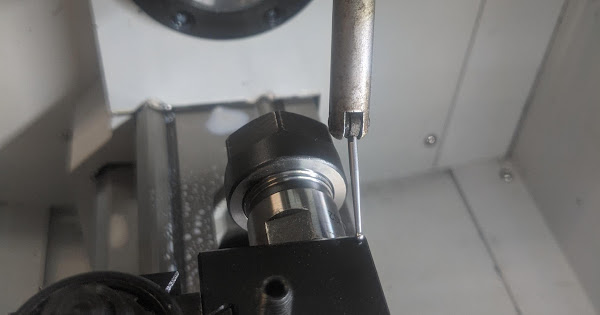

The machines seem to be great, but these damn toolposts should be thrown in the garbage… absolute Chinese junk!!! Don’t believe me…take a look at the pictures I’m including. It’s not just one piece that’s the problem either, otherwise they would all run out the same amount from end to end. I had indicated each holder dead nuts at the morse taper big end and you can see where my center drill ended up…thats what prompted me to begin my investigation. There’s no way to make accurate holes trying to drill with this garbage. I’ve always wondered why the only way I could get an accurate hole was to bore it…now I know why. You folks at Tormach should be ashamed to make such a good machine and put such a worthless toolpost on it.

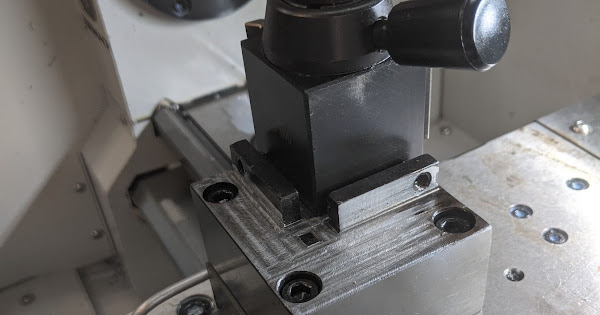

After taking the toolpost, and the toolpost mounting block off and grinding the bottom and sides flat and square, milling the top flat and square to the rest of the block, then grinding the toolpost dovetail angles square to the rest of the toolpost it’s looking much better. The sad thing is that a lot of folks that buy these lathes don’t have the equipment to even check these parts correctly, let alone have the equipment to grind them to straighten them up. I said it before and I’ll say it again, you guys at Tormach should hang your heads in shame allowing such a good machine out the door with such a terrible toolpost and toolpost mounting block on it. No wonder these machines get the reputation they have with some folks. As you can see from the pictures I’m including, it’s not perfect yet, but it’s much better than it was. I’m sure to get it the rest of the way I’m going to have to grind the dovetail angles of the tool holders as well. At least it’s close enough to actually be useful now.

Does anyone know if there is a store that sells Larry Phillips, because I really need one for my shop. I tried putting an add on Craigslist “Looking for old machinist to tell yell at young machinist “You’re not doing it right!” But no one responded.

I don’t know…I’d guess that I’m a pretty good candidate for that…lol

Well if you near the north of London stop in.

Do any of the big names make the small tool post? I really like Dorian but have been unable to find anything smaller than the axa size. I guess maybe i should just switch to axa and get a Dorian.

I’ve considered going to a good, (ie. Not Chinese ), AXA as well. I’ve actually reground some of the holders and the toolpost as well and it seems pretty good now. I guess ya gotta look at it kinda like a suburban u grind tool. ![]() . If you have the time and equipment to grind and check it it’ll actually make a pretty good toolpost.

. If you have the time and equipment to grind and check it it’ll actually make a pretty good toolpost.

So when you got this machine did you set it up and start working and then notice the posts were off? Or did you set it up start measuring everything and notice the tool posts out of spec?

Set the machine up assuming that the toolpost was correct. I indicated the toolpost itself in, but just assumed that the holders were as they should be… WOW was that ever a mistake. As I said, they’re all over the place. They look as if they were made by a bunch of 10 year old kids…and likely were.

All quick change tool posts are subject to movement is X,Y, and Z. With the fluidity of tool location I never use the post itself as a reference. I always use the loaded tool. Chuck up a piece of drill stock and indicate that for chucks. Even the Aloris tool posts have inaccuracies. If you insist on blocking the post in you should put adjustment screws on the blocks so you can move it by angular increments.

I have that, but the problem is that the bores of the morse tapers are not true to the ground dovetails. I understand slightly inaccuracies, but these Tormach ones are just all over the place. I indicate the tools in the holder, but that doesn’t help when you have one holder indicating the way it should and the next holder is sitting at an angle. I can’t take the time to indicate each holder every time I change it.

You should take the time. In a professional environment you cannot afford to not take the time. Lack of due diligence makes scrap parts. Turning and facing tools are not as important but drilling and boring tools have to be indicated each time they are installed in the machine… Threading tools are the most critical. If the V is not straight it will either bind or gall and stick half way into the mating threaded part.

Look dude, my guess is that I’ve been doing this way longer than you have…over 35 years in the trade and 15 as a shop owner… every piece that goes out of my shop is to print 100 percent. I can’t help it if you don’t understand the problem or what the solution is supposed to be. Those toolpost are supposed to be absolutely 100 percent interchangeable once they are indicated in. The ones I have are not and when you’re doing it for a living you cannot take the time to indicate them at every tool change. That just defeats the purpose of having a CNC. Sorry for being so blunt, but you really just ain’t getting it.

Thin skinned people around here are hilarious. Why are you using more than one MT holder? Would it not be as easy to pop the tool out of the tapered, indicated holder and pop another one in then bring up the next tool number? You know like if you had a tailstock. I’ve been doing this since 1992 and have had to make due with a lot of substandard equipment, Shop owners like yourself don’t seem to care about the state of the equipment the employee still must make a good part. If you are so high speed and such a staunch professional why would you buy a hobby grade machine and then purchase the hobby grade accessories? One prickly post deserves another. this is a discussion forum for a common interest product. No need to get all pissy. No need to have a “my penis is bigger than your penis contest”. I was actually sitting here thinkin if you must change multiple tapered holders gang tooling might be a better option. Or maybe a spacer set up between your boxed in walls you’ve made around the quich change post to turn the different holders straight to improve time management. Definitely a waste of my time to be interested in your problem. No brainstroming or discussion allowed with the know it all prickly I’ve got one year of experience repeated 35 times people who obviously run on “If I thought it up it must be right and that it if you don’t support my thought I lose my shit crowd” You just came here to WOW us with your stellar abilities. Congratulations man. You have done an outstanding job fixing that cheap crap you purchased and you should be awarded for your efforts.

Look, we got off on the wrong foot. I tend to take things a bit personal when someone questions something that I know is correct, and I know for a fact that these toolpost and holders are definitely not correct. You’re absolutely correct, drilling and boring tools are vital that they be correct as well as tapping. I do however take exception to them needing to be indicated every time. If the holders are correct and you have your offsets set correctly there’s absolutely no need to indicate them every time. This is just my opinion, and as such I support your right to have your opinion as well. There’s no laws against being wrong…weather it’s you or me. This thread started out with me making a post about these junk toolpost and holders so that others won’t think they have something that they don’t. I expect brand new tools to be correct…possibly you don’t and that’s ok too. And yes, while I could use one holder and swap out the tools in the tool holder, why would I??? That’s what a quick change toolpost is for. Now hopefully we can bury the hatchet on this and get back to discussing something that’s hopefully way more productive than this.

Speaking about not being able to trust any measurements. Have you ever noticed that when you probe tool lengths path pilot adds .001 mm to the measured length? But if I repeat the measurement it adds another .001mm.

@Dr_Harold_Jones are you referring to the 8L or a mill? I would like to know more about what you are seeing. Can you send me a PM with the steps to reproduce what you are seeing?

@Dr_Harold_Jones I just tested this on an 1100MX running 2.10.1 with our ETS and did not see what you are seeing. I checked the same tool many times (10+ times) and saw the measurement float around 0.002mm from the initial measurement but it did not continue to increase and this deviation is well within the expectation of this machine. If you continue to have issues with tool measurements then it might be worth it to get a Tormach ETS.