I am wondering what changes others have made to their 8L stands to stop coolant from splashing out and running onto the floor? Getting tired of having to get the shop vac out every time I run coolant. I think the majority is splashing out of the coolant tank as the coolant runs from the chip tray down into the coolant tank. There is a little coolant that is escaping from the front of the chip tray by running down the rails and dripping through gaps in the stand. What is the best sealant to use? I’m assuming that automotive rtv that is oil resistant will work?

On the 15L it will run through the spindle bore and run out on the floor. I used an air up rubber bladder from the plumbing store to stop it. On the left edge of the door on the enclosure coolant can spray out. I set up a piece of stainless plate to stop that.

On the right side of the door I covered the edge with vehicle trunk weather stripping to stop splash leaks. It has helped tremendously but fluid still drips onto the automatic oiler when the door is slid open.

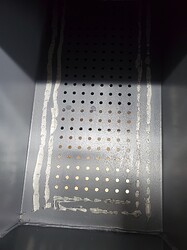

I found a video on YouTube by Accu-Slice of modifications he made to his 8L lathe stand. He glued a liner into his chip tray to keep coolant away from the walls. He also put a removable tube that directs the coolant right down into the coolant tank to help alleviate splashing. I’m trying some variants of what he did. As a quick and dirty experiment I sealed the outside two rows of drain holes with some rtv.

I also attempted to seal up the the drip tray with rtv.

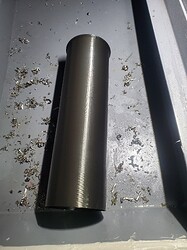

The last addition I made was an easily removable 3D printed tube to direct the returning coolant low in the sump to help reduce splashing.

After I’ve used the lathe for a while I will report back on the effectiveness of these modifications.

Wonder what they changed! I have one of the first 8l lathes with stand and with over 2 years of use no coolant on floor anywhere. I do get some in the motor enclosure thru spindle and some drains back thru the drain holes on each side of the cast iron base. I do vacuum out that area after each use to avoid coolant build up in the motor enclosure. The only other annoying coolant issue is it dripping off of cover and onto me when I lift it to change tools.

After using the 8L with the above mentioned modifications there is no longer coolant making its way to the floor. Now the only coolant on the floor comes from opening and closing the lid and it is only a few drips from each open and close cycle. You can mitigate the amount of drippage if you blow the drip edge off prior to opening the door.

On mine I went and got a sink drain fitting so the coolant has a lower point to drop into the holding tank.

I finally made the same modifications to mine and it cured the coolant river that was flowing from under my 8L. Thanks so much for the heads up on this much needed modification to cure an extremely prevalent problem.

I received a message from Stephen asking for the file for the tube that I printed, so I am adding it to this thread. The tube was printed on a Bambu printer using black PLA filament. The tube has been in use since March of 2023 and is still fine. My coolant doesn’t seem to be affecting it.

Lathe drain tube.stl (182.3 KB)