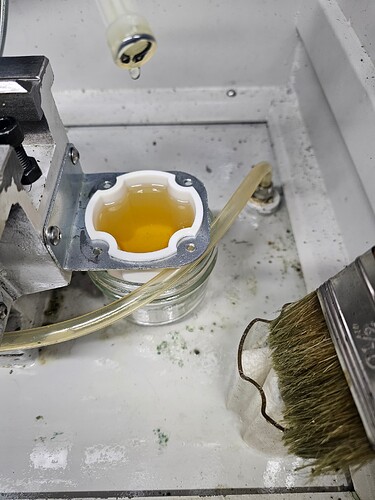

I have had my 8L since late 21. Saturday I came to work on a project and discovered that my oil tank for the manual oiler had broken right under the rim where it goes through the mounting bracket. I was wondering if any one else had experienced anything like that. I was hoping I could just purchase a new reservoir but the response I got from Tormach was that I would need to purchase a complete new oiler. I think I will attempt to do some kind of a glass jar workaround. I asked if the reservoir was sensitive to the coolant I have been using but didn’t get an answer to that question. I have been using trim 585xt. Has anyone else experienced a problem like this and if so how did you fix it?

Yes! And I think it was broken from day one.

Best I could tell, It was just hanging when I noticed the problem and touched it.

Lathe was still under warrantee, and Tormach sent a new one.

My solution for now was to 3D print a replacement. It is printed in PLA. I think it will work. I have tested PLA in oil in the past. Not sure how oil tight it will be. I have never made an oil container. I have way oil sitting in it now to test. If it works I will see if I can post a copy of the dxf file here.

Sorry I have a 1100mx assuming the oiler looks the same or very similar design.

I’d just make a metal one that fits the top part. The glass let’s you see the resivour is only half full, (empty, because the pickup can’t reach it) but you know as soon as you pull that handle that it’s empty. I would also put a oil resistant tube over the pickup that goes to the bottom of my new deep resivour. I’ll have a look at mine but it seems the pickup is self priming hydraulic so the pickup extension diameter might be critical.

It looks like the 3D print is going to work. I don’t know how it will hold up long term but after 48 hours of holding oil I don’t see any problems. If any problems crop up I will post it here. Here is a copy of the stl I created for this fix.

oil reservoir v2.stl (957.1 KB)

My repair used a 3D printed rim epoxied into the original broken oil cup, The repair is working fine and way stronger than the original cup rim.

Thanks for the reply Thomas, that looks like a great fix if the rest of the tank is intact. You should post the stl here. If you look at the pictures I posted you can see that mine also had a crack, on the bottom, through the injection point. It was already leaking before the rim fell off.

Tormach Oiler Rim.stl (141.5 KB)

Good thought! Here is the stl file. Note that it took a little filing on the pump tube side fit into the bottom of the pump housing.