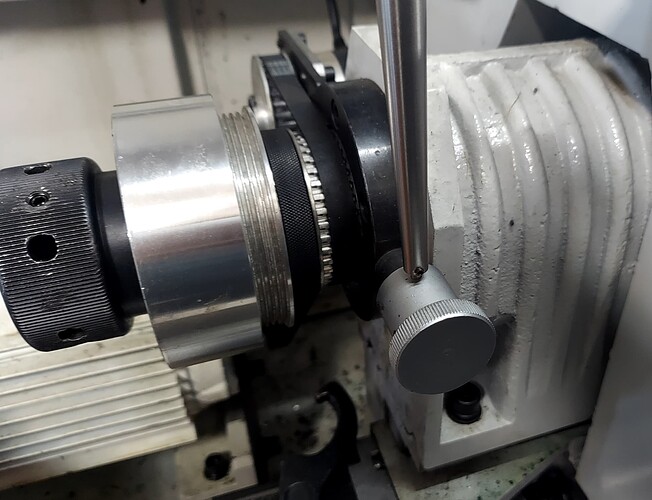

Thought I’d post a little modification that I made to my 8L that might help someone else. The issue I was having was trying to hold my stock against a collet stop, tighten the collet and keep the spindle lock pushed in all at the same time…I was definitely in need of at least one more hand. So my solution was to eliminate the need for the hand that was holding the spring loaded spindle lock in the locked position. What I did was use a die grinder to cut a detent that I could turn the spindle stop guide pin into so it will stay in and locked without me holding it…take a look at the pictures and it will make perfect sense. I realize that this locks the spindle without some sort of interlock to prevent the spindle from turning on while it’s locked, so anyone who does this, you’re doing this at your own risk.

3 Likes

My solution to this third hand required problem was to mark the top of the spring loaded stop and then remove it. I then drilled a 1/8" hole through the aluminum handle at the mark and into the screw-in post while the handle was depressed as if in the detent hole. I then tapered a stainless 1/2" rod for 1/2" to about 3/16" of an inch with the remaining 1/2 inch at a 1/8" diameter (see picture 1). Later I removed the 1/8" section and drilled a 1/8" hole in the tip and put a dowel pin in the end secured with a 4-40 set screw. This assemble is 7 1/2" long, so if I leave it in place, the spindle door interlock will prevent the spindle from turning.

1 Like