Hello!

I am having some issues with the 4-axis probing routines, I have tried both the axis and stock center 4-axis probing routines, and both routines aren’t finding the center of rotation OR the stock center.

I attached both sides of the workplace, it looks like the center is maybe 2mm off.

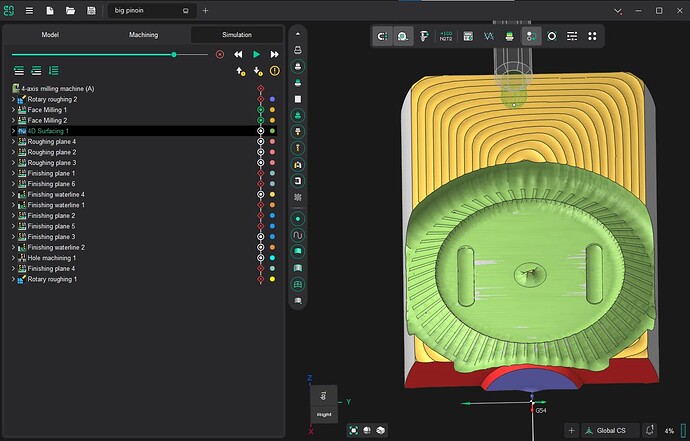

The encycam simulation shows that this shouldn’t be happening , I have remeasured the probe and tools a million times and still I have varying degrees of failed parts ( i suspect the z offset is off too).

I am on a pcnc 440 with a microarc 4 and am using the passive probe kit (PN 50355)

I’d like to think its a gcode problem with the routine in pathpilot and if i write the gcode myself then I wont have this issue but I dont know for sure.

Has anyone here had the same issue? I tried searching, but it seems like this combination of 4 axis use and probing has left me with an uncommon problem.