I see that the Tormach does not provide a tapping tool for the 440 yet there are a couple of videos showing the 440 easily tapping 8-32 threads in aluminum. Has anyone here modified the mill to perform tapping?

Using single form thread mill cutters, you can create internal or external threads of just about any size from 1/4-20 on up to whatever size you want! I just did some external 1" 20 threads per inch on my 24r router! Also, I would think a tension compression tap head would work fine for small internal threads around 8-32 or smaller on a 440 machine. Thread mills are expensive but will cut a wide range of custom or standard internal or external threads with just one size thread mill.

Thanks for the reply.

I wonder why the tension/compression tool is listed as “not compatible” with the 440?

I didn’t know that! I assumed a 440 had about same abilities as a 770 or 1100.

T.C tap tools are a simple tool to use. I have 2 collet units and one with quick change collets. I use them all the time for small sae and metric threading on my 1100. As I mentioned above, I use thread mills for 3/8 and larger internal and external threading.

I don’t believe that the spindle on a standard 440 can be commanded to run in reverse (required for a T/C tapping unit). David Loomis has a mod to overcome this limitation. See PCNC440 Goes Backwards - YouTube for further info.

Correct. The stock PCNC440 has a forward only spindle. Therefore in order to tap you would need a thread mill. You have to drill a pilot hole and use a thread mill to cut threads. Harvey Tool, also, has a pretty good selection of thread cutters.

Here is a video from NYC CNC that goes into pretty good detail on this process.

Just curious because there are several sources of information, but some of it is contradictory. I wonder if there is a solid reason why Tormach doesn’t sell the 440 fully functional since it appears all the capability is already in place except minor software changes.

Bob Abbott Tormach 440 tapping 8-32 threads - YouTube

David Loomes Tormach PCNC440 does tapping - YouTube

Linux CNC PCNC440 spindle reverse - LinuxCNC

Richard,

Quote simply, promoting the use of a USB I/O module to add this funtionality in a way that completely bypasses our electrical and software safety mechanisms is something that we cannot and will never promote. 440’s in particular are a product that sees significant placement in schools, and with students specifically those safety mechanisms must be the number one priority. “I understand for students, but I’m the only user of my machine in my garage and I accept the risk” I anticipate being a common response, but whether or not an individual user accepts risk on their part does not negate that any direction or recommendation Tormach makes is information available to every user. We’re proud of the community that pushes the limits of our machines, but it must be accepted that the community will push the machines in some directions past what the company can champion.

Every single product that we (or any company) releases represents a series of compromises, and in the specific case of the 440 the decision was made to use an MX3660 which does not have an output available to use for signalling reverse. Other considerations that would have given the ability to reverse the spindle would have eliminated the posibility of using a 4th axis and the success of the Microarc (personally my favorite of our accessories) have shown that to be the correct decision.

Thank you,

Norman

Hmmmmm, yeah, OK. So it’s dangerous to reverse a 440 but safe to reverse all the other machines.

Something in this story is missing …

Richard, I think that you are misinterpreting things. Tormach chose to use the MX3660 and it lacks a spare output for spindle reverse. It is not dangerous to use reverse but some of the ways that users have found to implement reverse may be dangerous in some environments.

The fact is that there is an unused reversing input for the spindle on the spindle driver and Tormach offers a USB M-Code I/O Interface Kit which apparently (I have not used one and don’t have one) that apparently does exactly the same thing as the aftermarket board described in several videos. I have no desire to void the warranty on my new 440 so this whole question is academic but there appears to be no technical reason for not offering spindle reversing. If no 4th axis is installed then then there can be no issue with access to that device. If it’s only a liability thing then the “official” response here is a bit disingenuous. Is it purely a marketing thing?

@Richard_Boggs

Yep, you could use a USB I/O kit and connect it to the spindle drive in the 440 to get your spindle to run in reverse. It won’t void your warranty. It’s a solution that works, but we felt like it was too much of a “bubble gum and duck tape” solution to recommend. We decided to use the available IO for a 4th axis because we thought that threadmilling was an acceptable (and in some ways superior) alternative to tapping with a tension/compression head. No marketing was involved in this decision, just our preference to give the 4th axis priority.

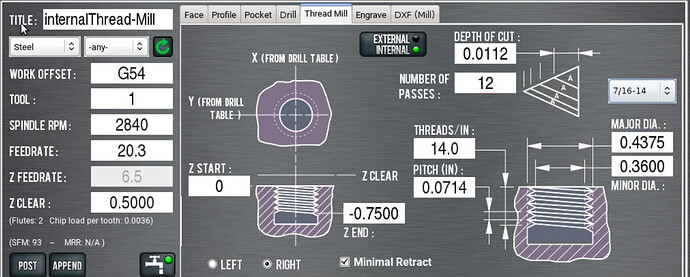

If you haven’t tried threadmilling I really recommend giving it a shot. The thread quality is better than tapping, you can easily program to the very bottom of a blind hole, one threadmill works for multiple sizes of thread (inch and metric) so just a couple of mills will allow you to make just about any thread you could tap on a 440. PathPilot makes it really easy to program too:

The thread drop down contains the settings you’d want for almost any inch or metric thread. Plus you can create threaded bosses (external) with these tools, something taps won’t give you.

Thank you for clarifying this issue, Daniel. Your explanation validates my thoughts about this and gives me confidence to try thread milling the #6 and #8s I use very frequently. To be honest, nearly all of those threads are through holes in aluminum and are quickly tapped with a hand drill. I just bought the 6 and 8 thread mill tools so will give it a try. If I find I can’t live without reversing at least now I know it can be done.

Thanks again.

Richard, not sure if this helps but on my 440 I needed to tap a series of 2-56 holes (blind) to mount some mighty bite clamps. After drilling , I used the drill table to reposition the spindle over the holes and a tap guide in a chuck to hand tap the threads . The Z was adjusted with the jog wheel and the operation was really quite efficient compared to any manual ways I have done that before. Not sure thread milling is realistic at that size. It did work fantastic for 3/8 tapped holes even for a beginner like me. I can’t say enough good about the PathPilot control and interface as it is just fantastic!