Has something changed with the 1100mx spindle cartridges? I cant seem to get more than 3 months out of them lately. No crashes.

Are you running 10,000rpm 24 hours a day cutting blocks of tungsten? Something is definitely wrong.

Hard to determine any cause based on the information provided. I’m on my 3rd spindle since upgrading to the MX version in 2023. The first was absolutely my fault thanks to a big crash. The second seemed to go pretty quick with no good explanation. I ended up rebuilding my original one on my own following this video and it’s been running ever since. Eventually I’ll get around to rebuilding the other one as well so I have a ready spare. There’s a guy on the facebook groups that’s been working on a commercial rebuild option as well that is expected to uprate the spindle to 15k rpm continuous duty.

Yea but 3 spindles in a year indicates a problem. If your buying whole spindles from tormach I would think that is at least a tormach ticket issue. Can we have a little background on how many hours on the latest spindle and what are you cutting, spindle speed? From what I understand a spindle should run a tool until the tool fails or overload shuts down the motor. How are the spindles failing? (Bearings I assume but are the bearings melting or ceasing or just developing slop?)

After watching a recent Audacity Micro video - I now use 9000 rpm as a max for my 1100mx

but I know a new or rebuilt spindle is in my future - Ben if you can share some tips on removal and replacing a spindle - what challenges did you have …etc.

Ed

Uh… that’s great for you. Tell someone near you that you might have had a stroke. Because none of that makes sense.

not sure what your issue is

must be British humor i suspect

Here is a link to a recent Audacity Micro video - where they interview a guy who makes good money on Xometry using a Tormach - he changes spindles ever 6 months from what I remember

Okay, little back story then. Machine is used in a production type setting cutting aluminum for an average of 60 hoursish a week. (500-10,000 ripums) lots of minishear time…We understand that we will not get the best spindle life out of it running this way. I actually have been going through the parts as we make them to reduce some of the higher end rpm operations. But, that doesn’t seem to increase the life. first spindle lasted the longest at about 1 yr but we weren’t quite as established as we are now therefore it didnt see the load it does today. I guess my main question would be have they changed suppliers/specs in the past year or not. Also, questioning running the warm up cycle(we currently do) or not. Just seems to add to the ware and tare on the spindle. Have been contplating rebuilding them but just ordering one and knowing it should be “good” for awhile seems to have worked for us until now.

Failures vary from bearing getting hot and causing drag. Spindle will fail to get up to requsted rpm.

Chatter on the parts due to slop. Last 3 both started to occur.

Well knowing what I know of mechanical engineering I would say that the most likely cause of increasing grate of failure is down to the instillation or wear on the spindle mating surfaces. This by no means imply that you don’t know what you are doing, more that as your familiarity with the process increases important parts of the install process are not completed with the required accuracy. While less likely the mounting surfaces can wear, bolts stretch, threads wear and all of these things can contribute to failure. And as you stated there could be issue with the new spindles. It’s probably down to all of these factors coming together in an impossible to decipher mess. First thing I would do is get tormach service involved. Then inspect the bolt holes in the head and use new mounting hardware. Third, go over your install process a make sure you are going by the book.

Please also let us know what happens.

You didn’t mention any tool or tool holder issues but you might put some engineering blue on a tool holder and load it into a couple spindles. Also if you can have someone take a look at your spindle bearings they should be able to tell you if they are all failing from the same cause.

I have been waiting for a year on an update to the “exploding tool changer springs” I hope the springs quit exploding.

I have 770MX.

I assembled the mill and made a few parts ,but was just learning the cam sid of things. Seemed to be getting more chatter than I thought I should have. I came across a video on YouTube where a guy went step by step through bearing R&R. Very detailed. I decided to disassemble, clean and regrease. Wash out preservative oil and dry completely, and grease. Oil dilutes new grease. Also fixed some lube problems. After that I tightened gibs and checked for head and table play. Z seemed excessively loose. Belville washers were lubed with antisieze on contacting surfaces. Snugged those up a bit for more holding power. I previously overhauled the 15L, top to bottom.

Sounds like play stackup could be part of the problem. Under torqueing bearing nuts can kill them too. They should be warm but not hot. 120deg? I can check on that one. One spring pass and I’m within 6 tenths. Aluminum.

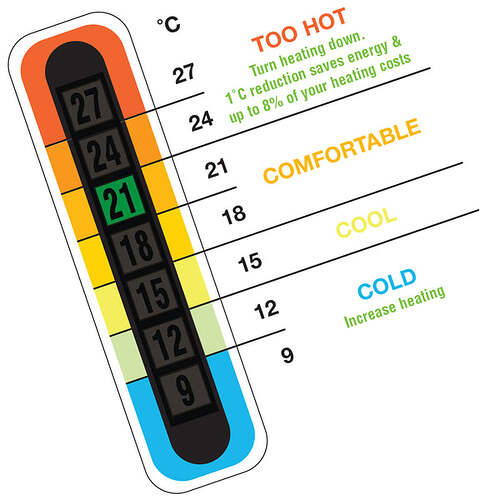

I saw this Color change thermal paint 20 years ago, they were using in formula 1 cars that would change Color like those thermometers in the 80s.

Why don’t we have this? Just need the range to be 90-300. 90 is safe for human contact, 300 is about to autoignite oil. I would stick / paint everything with it.

Some helicopter drive shaft bearing holders use heat sensitive paint among other uses.

I bought a new 440 mill, you could hear the spindle cry from my neighbors house! Tormach gave me grief and eventually replaced the spindle. They claimed nothing was wrong? I used a Haas for so many years of abuse! The spindle is original and still running.

Any luck? I’m curious about this.

New spindle installed and running. No breakin cycle nor warm up cycles. We will see how long it last.

Ben

Any change you would be willing to sell one of your failed spindles ?

you have quite the collection

thanks

Ed

Just came across this subject. I have a PCNC1100 S3. The original spindle lasted about 4 years cutting plastics (probably equal to a total of 8 months cutting). Went bad when I started cutting aluminum fairly regularly. Now I am on my fourth spindle in two years and that doesn’t include two spindles that were DOA. After installation they groaned and screamed like they had NO lubrication! Tormach replaced them both on a trouble ticket. I have rebuilt 2 spindles like they show in the video. (I have rebuilt Bridegport and Boyer-Shultz spindles with success). But the Tormach spindle rebuilds all run hot with very little-to-no preload (190F at 2000 RPM for an hour). I think they may have changed suppliers or the QC on them has gone away.