I found a plain back 2J Hardinge Sjogren locally for a pretty good price. It came with one 7/8 collet. The 3 jaw chuck that came with my Grizzly lathe is junk. I have purchased a 5c collet closer and an er40 collet closer. I thought this would be a good item. Buyers remorse set in after purchase because used collets are $30 dollars a piece. I can buy a super nice Buck or Bison chuck for the money required to get a full set of collets. Searching the web, I found a full set for $250. The set, however came with another D1-3 Camlock speed chuck. That is how the 15L got involved in this project. Caveat emptor, the shars and similar brand of d1-4 and d1-5 plain back adapters that run $100 are cast iron and not made from bar stock. I don’t have an issue with the structural integrity of cast iron but it creates copious amount of black dust and when mixed with coolant coats the inside of your machine with a black film. It took longer to clean the machine after turning the adapter than it did to machine the part itself.

I installed the plain back chuck onto the manual lathe first. That was a mistake. The plain back has 4 bolts that go all the way through the chuck. easy to machine and mount. The D1-3 is integral. The bolts in the front hold the chuck together. I had to use the 7/16-20 camlock stud threaded holes to mount the chuck to the adapter. This hole pattern is so small that the heads of the bolts interfere with the 5c integral nose taper on the 15L spindle. That meant the adapter had to be thicker than desired and I had to buy flat head cap screws to get the bolts low enough in the adapter to not interfere with the tapered nose.

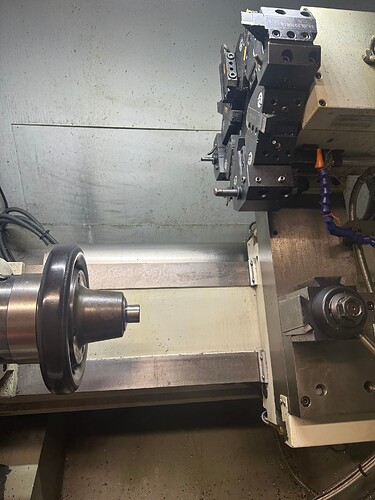

One of the downside of boring on the 15l is that they did not engineer a catch basin with door to divert coolant that makes it way through the spindle tube back into the enclosure. Here is my fix. a catch basin is a project for another day.

I received a complete set of 1/16 graduated collets, 1 square collets and a few 32nd and 64ths in the mix. Total expenditure with plain back adapters was $700, Was it worth it. Maybe. Maybe not. This is my hobby as well as my career and I seem to have an affinity for work holding devices. The project was fun. The rewards will be realized in the future.

Nice job.

Real estate is always a problem. Have a lever operated collet closer on my 15L. Just like quick action and fine tuning grip.