My 15L lost it’s zero last night and killed a boring bar. I really didn’t know what to think about it so I re-zeroed and carried on. Tonight it trashed a $250 face grooving tool. Now my feelings are really hurt. Any ideas. I can’t trust it now so I’m out of business until I figure it out.

Huh

Any change to post processor? Strange G coordinate slipping in somewhere?

One thing I did after I had my 15L for a while was move the E stop button on the keyboard platform.

It is extremely easy to actuate even though the button isn’t pushed in. Hair trigger. The one on the cabinet you can’t do much about but avoid it. Is that what is happening or is it just going off on it’s own? Might also check reference switches, clean them. Mine would get gummed up with coolant. I eventually trashed those for dial indicators and manually reference. Don’t know if replacement switches are any better.

On a side note, do you have the new X stepper motor with the integral brake? It is PN 35432. You can look on the website to see what the connector box looks like. Would you look at the C1 contactor in the cabinet and see if one wire 328 or 329 is in one of the top terminals and if 328 or 329 is in one of the lower ones? And in which order and terminals for me? Ordered a new stepper as the early models didn’t have the brake.

thanks

35452

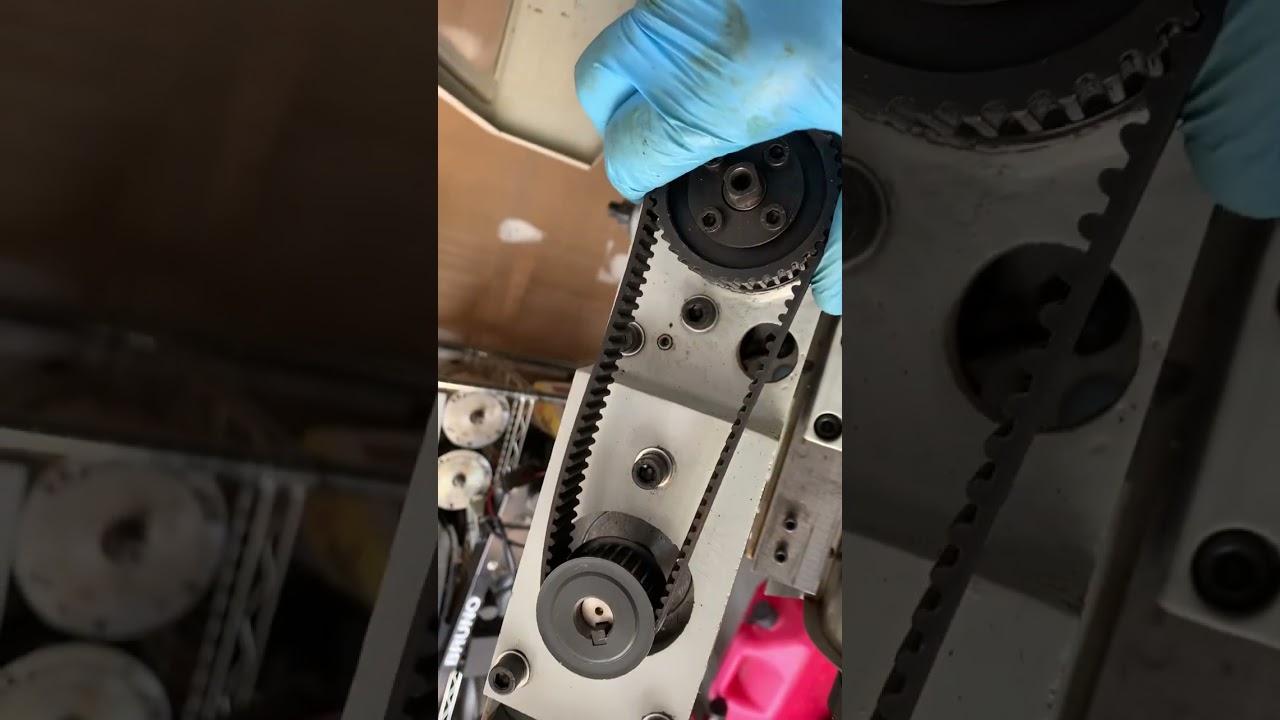

One other thing, check the pulleys on the ball screws. Inside are cone washers and there are 4 clamping screws on the top. If those are loose, then the pulley can slip under quick movement.

Bruce,

Sorry it’s taken so long to get back to you. My day job has eaten up a lot of my time lately and this project has suffered. As for your suggestions, I’ve checked all of those and the few that Tormach support has given me and come up with nothing. G-codes, E-stops and switches weren’t ever a possibility because this thing starts up and some times makes 3 or 4 good parts and then in the middle of any random proceedure it acts like it forgets where it is and jams the tool into the part. tonight it was boring and on it’s third pass it went rapid about .300 too far before it started the pass. Luckily I was testing on aluminum and the passes were shallow so I didn’t loose a tool. I replaced the motor driver for the Z axis hoping that was it after I did an ohm test on the the motor out found it good. I’m at a loss and getting pretty close to calling Haas and letting someone else hold this one.

I have had similar a similar issue with my Mach3 mill. My workshop building is a little under powered. If I use the mill and lathe at the same time the mill will lose its place and just continue on a straight cut. The lathe was stealing all the power. Now I just run one machine at at time.

Intermittent problems are the worst. When I got my lathe, I double checked all the connections, IE the clamping screws at all the connectors. I actually found a couple stray wire strands poking out close to other wires. Maybe loosen, wiggle, and retighten every one you can get too. Especially the Z axis wires. Check grounds for corrosion, and paint underneath.

Is the filter on the bottom of the cabinet dirty? Fan running? Might be a temperature thing. really sounds like a bad connection or chip internals breaking down.

Maybe pull the mother board and look it over carefully under magnification. Poor solder joint?

I had a problem with the main power switch when I first got it. Would power up, but wouldn’t turn off!

Keep hunting…

Did you by chance override the rapids? The default Rapids are 60ipm, you can type ‘Admin Rapid…’ and select the option to show. If it is over 60ipm reset it back to 60, steppers can get into a locking mode if trying to spin to quickly. I had bumped mine to 100 then noticed problems when jogging with steppers loosing steps because the rapid pulses were to high an RPM for the steppers.

Richard,

I’m using Fusion 360 and not the conversational but I did check my rapids and they are at 40 ipm

You can up that to 60ipm as that is the factory standard for the 15L, I would also check your belts maybe what you are experiencing is compounding belt slippage.

I also had loose belts and they jumped the gear tooth during some cuts.

Were they noticeably loose? Mine feel really tight. no deflection when i push them.