Just wondering if broaching is possible on the 1100mx. If so what is the recommended way to lock the spindle?

Just to be clear I want to broach brass, aluminum and possibly mild steel. Small gears and key ways for very tiny gears.

@Dr_Harold_Jones There is no spindle lock for broaching on the 1100MX

Have you looked into rotary broaches? We don’t sell one with a bt30 but there appear to be some options out there.

I’m not (yet?) a Tormach owner, but…

I have gone down a deep rabbit hole in making rotary broaches. I have a description here of how to design and make a very simple rotary broach holder for broaches of arbitrary size, using only round stock and a bearing ball or two. Any particular holder of this design is specific to one length of broach.

Hemingway sells an inexpensive kit that doesn’t take long to make; I’ve purchased and made it. I’ve also created a similar design that doesn’t put an axial load through a radial bearing, is made mostly with the parts they ship, and is intended to be additive to their kit rather than a replacement for it. I also have a design for a floating rotary broach holder (accommodating a range of broach lengths without adjustment) that hasn’t been much tested yet; if anyone wants to try making that, let me know that you are willing to test the design (and, inasmuch as the design is confusing, my instructions), before I publish it more widely (or decide based on feedback that it is junk that shouldn’t be publicized).

A rotary broach probably won’t be of use for keyways. It shouldn’t be too hard to design and fabricate a manual spindle lock for any of the Tormach mills, though, if you have enough keyways to broach to warrant the effort. Otherwise a regular broach and an arbor press might be the way to go.

Polygon suggests double-keyway rotary broaches:

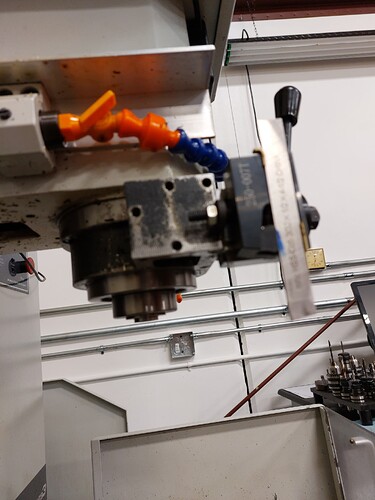

I have done a little broaching of keyways using my PCNC 1100 Series3 and the RapidTurn toolpost holding a parting blade. James at Clough42 on Youtube inspired me. I wrote a simple program to make the repetitive moves as well as move side to side to cut the width of the keyway. The part in the picture is 4140 Steel, I will attempt to attach some pics and the program, the video won’t upload.

Text of the Program

(Description = BROACH TEST)

(Units = G20 inches)

(Work Offset = G54)

(Tool Number = 105)

(Tool Description = 3/32 .098 PARTING BLADE)

(Tool Y HEIGHT = 0.506 inches MIN FEATURE SIZE)

(Spindle RPM = )

(MANUAL EDIT OF FACE A BLOCK)

G17 G90 (XY Plane, Absolute Distance Mode)

G20 (units in inches)

G54 (Set Work Offset)

T 105 M6 G43 H 105

o100 sub (STROKE)

G1 Z-1.115 F50.(DOWNSTROKE TO Z DEPTH)

G0 Y[#104] Z-1.1 (RETRACT TO Y START W/LIFT)

G0 Z0.3 (RETRACT TO Z CLEARANCE)

G0 Y[#102]

o100 endsub

#101 = 0. (X CENTERLINE)

#103 = 0.075 (X +/- JOG FOR WIDTH)

#104 = -0.110 (Y start position, negative, counting up to stop at 0)

#102 = #104 (Current Y position, set to start position)

G0 X0. Y[#104] (go to CLEARANCE Y pos)

G0 Z0.3 M8

o110 while [#102 LE 0.0001]

G0 Y[#102] (MOVE TO NEW Y)

G0 X-[#103]

o100 call (CALLS STROKE SUB)

G0 X[#103]

o100 call (CALLS STROKE SUB)

G0 X0.

o100 call (CALLS STROKE SUB)

#102 = [#102+.002] (increment #100 by DOC)

o110 endwhile

G0 Z2.(Go to rest POSITION)

M30 (end program)

That’s a pretty neat idea. I wouldn’t have thought of that.

very neat indeed. I saw ThreadExpress (youtube) do something similar.

Does your machine have a spindle lock? Can I see what this magical thing looks like as the ones I have seen online are either a box wrench cut in half and screwed to something or some kind of internal mechanism that isn’t visible.

He is using the Rapidturn kit. No spindle lock needed. This hangs off the side of the spindle. Tormach Cutting Tools - 0XA Tool Holder Starter Kit for RapidTurn - SKU 37175

Yeah, what he said.

A couple notes:

Had some trouble originally with the toolpost shifting while turning (before broaching), I ended up pinning it to the clamp bracket and putting a pin in the bracket that goes into the socket head of one of the spindle screws.

The Z travel speed limits your broaching speed. Not so on an MX? (Sponsorships accepted LOL)

The parting blade tended to slip up in the tool holder.

You can broach in a blind bore!

The toolpost arrangement takes the force off your spindle bearings.

Not much tool orientation available, but you could put your 4th axis underneath and orient/ index the part.

Haven’t seen the broaching, but Cliff’s work with the RapidTurn really helped me out in the beginning, especially differential thermal expansion- the cast iron machine grows a lot less than than the aluminum Spindle housing and base!

I’ve done broaching on my 770 by locking the spindle to the spindle body. See (https://youtu.be/zADFgfaYZ0A)

To lock the spindle on the MX just do the partial activation of the pneumatic cylinder that locks the spindle for tool changes. I haven’t dug to see if there is already M or G code to activate that phase of the penumatic drawbar, but worst case you can just run a 1/4" push connect line into the cylinder directly, taken through a regulator to lower it to 50psi. Orient the spindle with your broaching tool in place, then connect that line and the cylinder will apply enough force to hold the spindle in place but not to release the tool.

I’ve also done it with a simple thrown-together 3d printer spindle lock. There should be almost no rotational force from the broaching tool so it won’t take much.